Published on 03/02/2018 | Technology

Industrial enterprises are undergoing one of the biggest transformations since the dawn of the industrial age. Digital technologies, sensor-enabled devices, data analytics and a shift toward a services economy are remaking the way companies compete worldwide. To help industrial enterprises adapt to these powerful market forces, several global initiatives have been created to help codify an approach:

No matter what you call if, all these initiatives define a common “Smart Factory” that bridges the traditional boundaries between enterprise information technology and operations technology. The Smart Factory uses

modern data science, sensor-enabled equipment, and digitization to connect business leaders to what’s happening on the factory floor, and actionable intelligence to make business more profitable, processes agiler, and products and services more profitable.

While the benefits and competitive advantages of embracing a Smart Factory model are well documented, several significant barriers remain, preventing many industrial enterprises from making the move to SmartFactories today, including:

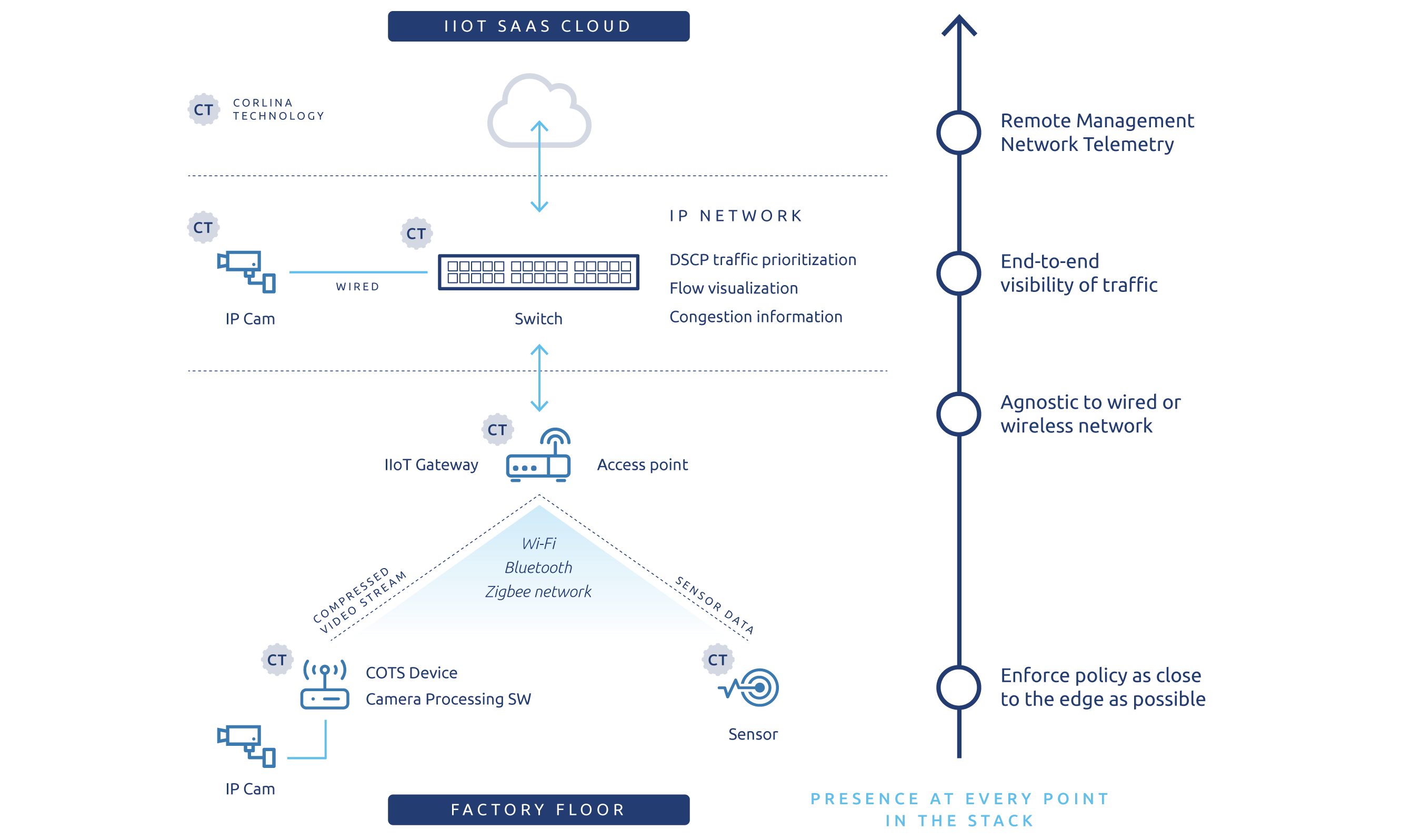

As part of the Smart Factory adoption effort, numerous sensors and cameras are being deployed on the factory floor, which increases the attack surface. The lack of end-to-end visibility in the technology stack makes cyber attacks on factory equipment more likely, while at the same time more difficult to detect and remediate.

Large global corporations are exploring the benefits of Smart Factory technology, pouring millions of dollars into exploratory proof of concept studies and multiyear R&D initiatives. However, for the millions of small- and mid-size industrial enterprises actually driving today's largest economies, these expensive projects are neither affordable nor practical. Manufacturing equipment is replaced or updated rarely if ever, so solutions must accommodate this reality of brownfield compatibility, not just work for greenfield implementations.

Manufacturing operations are the lifeblood of an organization; adding technology to the factory floor cannot jeopardize these very same operations, whether during roll-out or on an on-going basis. Small manufacturers in particular must ensure their production facilities are not weakened by the addition of new equipment or new software solutions.Scaling Smart Factory capabilities to the larger market requires a different approach.

The Corlina Smart Factory System of Trust is the first affordable, lightweight, easy to deploy and easy to use the software as a service (SaaS) solution designed to bring smart Factory capabilities to the small and medium enterprises that make up the vast majority of the world's manufacturing sector. The Corlina solution provides a simple yet powerful way for smart manufacturers to profile, manage, and monitor the performance of connected devices, ensuring data integrity and operating system security. Unlike complex solutions that require new or specialized hardware and costly services to install, the Corlinasolution can be installed, monitored, and managed remotely from any location, anywhere in the world.

Corlina’s intelligent module (Corlina Technology, or CT) has a tiny footprint that seamlessly integrates into various points in the technology stack to monitor, track, analyze, and manage a large number of devices and data that comprise a Smart Factory initiative.Corlina's Smart Factory Dashboard then provides a real-time view into the operation of sensors and connected equipment throughout the factory, providing actionable intelligence and ensuring factory floor integrity. Key Smart Factory capabilities include:

Corlina modules can be easily deployed in just a few clicks on new (greenfield) or existing (brownfield) equipment, and don't require specialized programming expertise. A simple, intuitive user interface guides users through setup, and then begins to deliver factory intelligence in minutes.

2. Scalability:

Corlina's lightweight module can be rapidly deployed at a fraction of the cost on thousands, even millions of new (greenfield) or existing (brownfield) devices, while the CorlinaSmart Factory System of Trust delivers timely, actionable factory intelligence via an affordable, self-serve subscription model. One or multiple factories, at any location around the world, can be easily monitored from one Dashboard.

Corlina authenticates and tracks each device's location and state in relation to the network and the role of the device. As a first response, any deviation from a known baseline is correlated with observed patterns or trends, and factory managers are alerted to system anomalies.

Corlina provides capacity monitoring, device metadata, traffic information, and state information to correlate with the events within the factory floor IP network, giving factory managers real-time visibility into the integrity of their operations.Collected data is maintained in a secure and immutable manner.

Corlina provides a secure, affordable, and elegant way to scale Smart Factory capabilities into the millions of

industrial enterprises driving today’s largest economies.It is designed from the ground up to be lightweight and non-intrusive for the most restrictive host environments, with a distributed SaaS architecture built for scalability and resiliency. The adoption of smart factories starts with “connected devices,” and Corlina’sSmart Factory System of Trust provides easy-to-use tools that help bridge the gap between IT and OT teams. The data collected from multiple factories is normalized and shared across teams and departments

to improve processes and workflow.Large systems integrators and industrial equipment manufacturers can use Corlina’s Smart Factory System of Trust to facilitate interactions with partners and end customers. Adding value to their products and services.And Small and Medium manufacturers looking to adopt smart Factory technology now have a simple and affordable way to begin their implementation.

The Corlina Smart Factory Sensing Service runs on any Linux operating system and is in the process of being certified to work on third-party hardware systems including:

• Eurotech ReliaGATE 20-25 Multi-service IoT Gateways

• Advantech Pocket-Size Smart Factory Edge Gateways

• Intel® NUC

The Corlina Technology (CT) module runs on all Intel® X86 based servers and gateways that use

processors such as:

•Intel® Core™

•Intel® Xeon®

•Intel® Pentium®

•Intel® Atom

www.corlina.com | info@corlina.com