- Application Infrastructure & Middleware - Data Visualization

- Application Infrastructure & Middleware - Database Management & Storage

- Mining

- Business Operation

- Software Design & Engineering Services

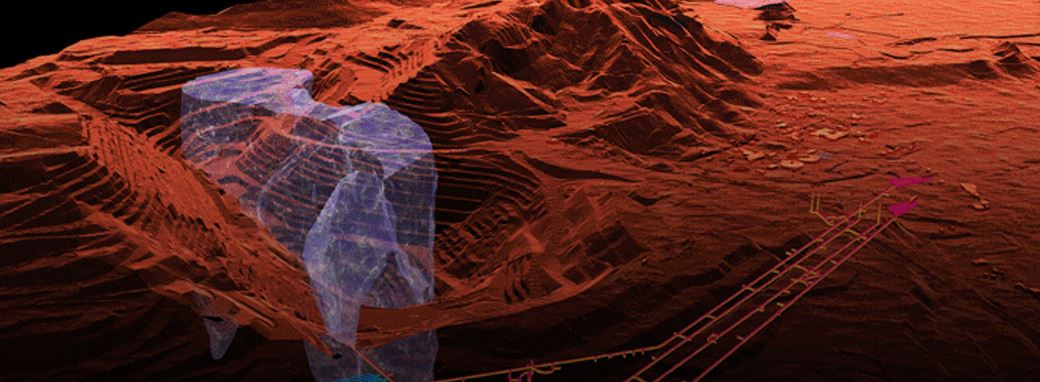

Argyle Diamond Mine

Argyle Diamond Mine, owned by Rio Tinto, is one of Australia’s oldest diamond mines. The mine has been operating since 1983 and has produced more than 800 million carats of rough diamonds. It is one of the world’s largest suppliers of diamonds and the world’s largest supplier of natural colored diamonds and is famous for its signature pink diamonds.

While Argyle Diamond Mine had an existing delay accounting system that was developed in-house, the challenges of a legacy system were exasperated by the departure of the in-house developer. As a result, the company struggled to remain up-to-date with the changes in the mining process along with advances in software capabilities.

Due to changes in mining operations, a large number of equipment events were recorded as text data. This made it difficult to search for trends since the system was dependent on user input, which was not consistent across each user.

The challenge for Argyle Diamonds was to determine which delay accounting system would be the best to implement given a limited budget and a well-defined set of needs: something scalable, capturing all delays at the plant level, with the ability to classify and search delay events.

After evaluating options ranging from an updated in-house system to Excel-based solutions to other automated systems, it was ultimately determined that RtDUET was the ideal solution for Rio Tinto’s Argyle Diamond Mine.

- The system is specialized in capturing, analyzing, and reporting on downtime events within a manufacturing environment; because RtDUET was developed especially for delay accounting, there are no additional costs for irrelevant modules.

- RtDUET offers production management the ability to validate data which acts as a secondary checkpoint.

- RtDUET is compatible with Argyle Diamond Mine’s data historian, OSIsoft PI System™, the system used to collect data on-site.

- Reporting features within RtDUET offer additional value.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.