Autonomous Robots

Autonomous robots are intelligent machines capable of performing tasks in the world independently of either direct human control or fixed programming. Examples range from autonomous drones, to industrial production robots, to your robotic vacuum cleaner. They combine expertise from the fields of Artificial Intelligence, robotics, and information science.The autonomous robot must have the ability to perceive its environment, analyze situational data in order to make decisions based on what it perceives, and then modify its actions based on these decisions. For example, the scope of autonomy could include starting, stopping, maneuvering around obstacles, communicating to obstacles, and using appendages to manipulate obstacles. There are few autonomous robots in operation today. Even most sophisticated, dynamic robots such as those used in an automotive factory perform according to static programming. And most autonomous robots are only semi-autonomous and will likely remain so even as more fundamental autonomy becomes technically feasible. For example, the Roomba vacuum cleaner does not move according to a pre-programmed route and can modify its route dynamically as its environment changes. However, it has a very limited degree of freedom that is determined by its programming.

- Heavy Vehicle

- Automotive

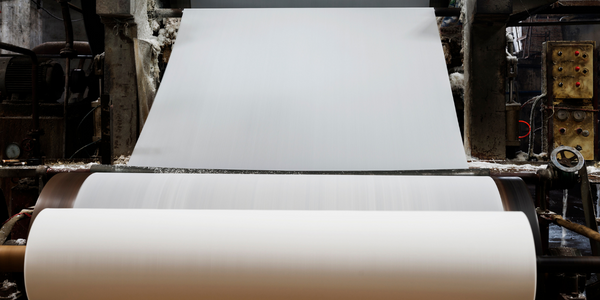

- Equipment & Machinery

- Discrete Manufacturing

The Boston Consulting Group is conservatively projecting that the market will reach USD 87 billion by 2025.

Source: The Robot Report

Electrical engineering company Siemens predicts the global market for autonomous robots to grow to USD 3.6 billion in 2019, and USD 13.9 billion in 2023.

Source: Siemens

The global autonomous robot market was valued at around USD 4.6 billion in 2016 and it is expected to reach more than USD 11.9 billion million by 2024. It is expected to grow at a CAGR of over 14% between 2017 and 2024.

Source: Global Newswire

When are autonomous robots practical?

Autonomous robots are particularly useful when one of the two criteria are met:

1. The environment is either dangerous or expensive for humans to operate in. For example, spaceflight and mine sweeping are both dangerous fields of human activity. Spaceflight is also extremely expensive due to the cost of supporting human life in space.

2. The task requires simple, routine action in high volume with a modest level of dynamic adjustment. For example, store-to-door goods delivery and highway trucking are both routine activities yet require the ability to react to unexpected situations within a range of possibilities. Likewise, in a production environment, a robot performs a largely repetitive action but must respond to unpredicted variables such as the precise orientation of a component it is assembling, or modification of the task in order to customize orders.

What are the core functionalities of an autonomous robot?

The concept of an autonomous robot is broad and can include a wide range of devices with very different capabilities. However, any autonomous robot should have some ability to perform these basic functions:

1. Gather and process information about the environment.

2. Work for an extended period without human intervention under unpredictable stimuli.

3. Move through its operating environment without human assistance (but with pre-determined constraints).

4. Avoid situations that it has been programmed to identify as undesirable, such as harm to people, property, or itself.

More advanced robots may be capable of optimizing their efficiency or adding new capabilities as they 'learn' through by processing data. The capabilities of robots can also be improved through system upgrades enabled by collective data processing. For example, a fleet of vehicles could receive regular updates that incrementally improve fuel efficiency based on the processing of their collective operational data under diverse driving conditions.

Business Owners and Executives: Business owners and executives are primarily concerned with the strategic implications of adopting autonomous robots within their organizations. They evaluate the potential benefits, such as increased productivity, cost savings, and competitive advantage, against the investment required for robot deployment. Business leaders also assess the impact of autonomous robots on workforce dynamics, job roles, and organizational culture, recognizing the need for workforce reskilling and change management initiatives to ensure successful integration and acceptance of robotic automation.

Operations Managers and Production Supervisors: Operations managers and production supervisors are responsible for overseeing day-to-day operations and optimizing manufacturing processes. They view autonomous robots as valuable assets for streamlining production workflows, improving operational efficiency, and enhancing product quality and consistency. These stakeholders collaborate closely with robotics engineers and technicians to design and implement robotic solutions tailored to specific production requirements, ensuring seamless integration with existing equipment and workflows while maximizing the utilization and performance of autonomous robots on the factory floor.

Robotics Engineers and Technicians: Robotics engineers and technicians are instrumental in the design, development, and maintenance of autonomous robots. They leverage their expertise in robotics, mechatronics, and control systems to create innovative robot designs, program autonomous navigation algorithms, and troubleshoot technical issues encountered during robot operation. These stakeholders work closely with manufacturers, integrators, and end-users to customize robot functionalities, optimize performance parameters, and ensure compliance with safety standards and regulations governing robotic systems.

Supply Chain and Logistics Professionals: Supply chain and logistics professionals recognize the potential of autonomous robots to revolutionize warehousing, distribution, and order fulfillment processes. They view autonomous robots as key enablers for increasing warehouse throughput, reducing order cycle times, and enhancing inventory management accuracy. These stakeholders evaluate the integration of autonomous robots with warehouse management systems (WMS) and enterprise resource planning (ERP) systems to optimize material flow, inventory visibility, and order fulfillment operations, driving operational excellence and customer satisfaction in the supply chain.

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms form the foundation of autonomous robots, enabling them to perceive, interpret, and respond to their surroundings intelligently. Deep learning techniques, such as convolutional neural networks (CNNs) and recurrent neural networks (RNNs), enable robots to analyze sensor data, recognize objects, and make real-time decisions based on learned patterns and experiences. Reinforcement learning algorithms empower robots to learn and adapt their behaviors through interaction with the environment, improving performance and efficiency over time.

Sensor Fusion and Perception: Autonomous robots integrate multiple sensors, including cameras, LiDAR, radar, ultrasonic sensors, and inertial measurement units (IMUs), to perceive their environment and navigate safely and accurately. Sensor fusion techniques combine data from different sensor modalities to create comprehensive and precise representations of the robot's surroundings, enabling robust perception and localization capabilities. Advances in sensor technology, such as high-resolution imaging sensors and solid-state LiDAR, enhance the perception range, accuracy, and reliability of autonomous robots in diverse operating conditions.

Navigation and Localization: Navigation and localization algorithms enable autonomous robots to determine their position and orientation within their environment and plan optimal paths to navigate from one location to another. Simultaneous Localization and Mapping (SLAM) algorithms enable robots to build maps of unknown environments while simultaneously localizing themselves within these maps, facilitating autonomous exploration and navigation. Real-time kinematic (RTK) GPS systems, visual odometry, and feature-based localization techniques enhance the accuracy and precision of robot navigation in outdoor and indoor environments.

Sensor Data Acquisition: Autonomous robots rely on various sensors, such as cameras, LiDAR, ultrasonic sensors, and inertial measurement units (IMUs), to perceive and sense their surroundings. These sensors capture real-time data on environmental parameters, including distance, depth, color, texture, and motion, allowing robots to create accurate representations of their surroundings. Data acquisition techniques, such as sensor fusion and data filtering, enable robots to integrate and process sensor data from multiple sources, enhancing perception and situational awareness in dynamic and unpredictable environments.

Data Processing and Fusion: Data processing and fusion techniques play a critical role in extracting actionable insights from raw sensor data and generating meaningful representations of the robot's environment. Signal processing algorithms, computer vision techniques, and machine learning models analyze sensor data to detect objects, recognize patterns, and infer contextual information, enabling robots to interpret sensory inputs and make intelligent decisions in real-time. Data fusion algorithms integrate information from diverse sensor modalities, such as vision, lidar, and radar, to create comprehensive and accurate representations of the robot's surroundings, enhancing perception and navigation capabilities in complex and cluttered environments.

Technological Complexity: Autonomous robots incorporate advanced technologies such as artificial intelligence, machine learning, sensor fusion, and real-time decision-making algorithms. Deploying these sophisticated systems requires expertise in robotics engineering, software development, and system integration. Overcoming technological complexity entails selecting suitable robot platforms, sensors, and software frameworks, as well as ensuring compatibility and interoperability with existing infrastructure and workflows.

Infrastructure Readiness: The deployment of autonomous robots often requires modifications to existing infrastructure to support navigation, communication, and power supply requirements. Ensuring infrastructure readiness involves installing navigation aids such as beacons, markers, or QR codes, establishing reliable communication networks for remote monitoring and control, and providing sufficient power sources or charging stations to support continuous operation. Retrofitting facilities and environments to accommodate autonomous robots may incur additional costs and logistical challenges.

Regulatory Compliance: Autonomous robots operate in diverse environments governed by regulatory frameworks and safety standards. Compliance with regulations related to robotics safety, data privacy, and liability is essential to ensure legal and ethical operation. Deployers must navigate regulatory requirements specific to their industry and jurisdiction, obtain necessary permits or certifications, and demonstrate adherence to safety protocols and guidelines. Addressing regulatory compliance concerns may involve collaboration with regulatory agencies, industry associations, and legal experts to interpret and navigate complex regulatory landscapes.

Case Studies.