- Automation & Control - Programmable Logic Controllers (PLC)

- Functional Applications - Remote Monitoring & Control Systems

- Networks & Connectivity - Bluetooth

- Networks & Connectivity - Ethernet

- Networks & Connectivity - Routers & Bridges

- Networks & Connectivity - Wireless Local Area Network

- Robots - Articulated Robots

- Robots - Robot Application & Programming Software

- Equipment & Machinery

- Discrete Manufacturing

- Remote Control

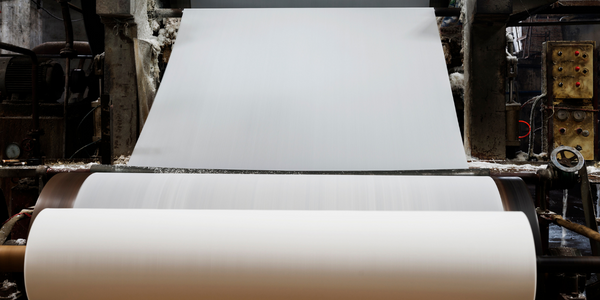

The round slitter blades that cut the paper in JSI’s machines are extremely sharp and can be dangerous to handle manually. Therefore, JSI and Millennium Controls designed a robotic blade-changing system using a robotic arm from Fanuc Robotics. The robot changes the sharp blades automatically, without operators having to touch them. But even if the blades can be changed automatically, operators still have to go up to the HMI of the machine which put them in close vicinity to the sharp blades. Therefore, JSI and Millennium Controls looked for a way to access the machine from a distance.

eWON Cosy allows remote access To access the machine remotely, JSI and Millennium Controls installed an eWON Cosy from HMS – a remote router which allows users to access the machine via the Internet to do machine monitoring or even programming and maintenance. This means that operators can change blades from a safe distance inside a plant or indeed from anywhere in the world. The eWON Cosy is connected to the machine’s PLC (a Rockwell ControlLogix L7). The router communicates with the cloud-based eWON Talk2M service where users can log in to access their control system. It is just like being connected on site — Users see exactly what they would see on the HMIs in on site. Wireless communication — Anybus Wireless Bolt With many moving parts in a machine, cabling can be difficult and cumbersome. By mounting an Anybus Wireless Bolt on the paper slitting machine, JSI can offer wireless communication between the PLC cabinet and different parts of the machine. The Wireless Bolt can communicate via Bluetooth, Bluetooth Low Energy and Wireless LAN enabling a very robust industrial wireless connection within a range of 100 meters. Connecting Modbus-TCP stacklight to EtherNet/IP The Allen Bradley PLC controlling the machine communicates uses EtherNet/IP —the preferred network of Rockwell Automation-based systems. The PLC communicates seamlessly with most other systems and components in the machine, but JSI wanted to use a stacklight to show the current status of the machine, and this stacklight used Modbus-TCP communication. To enable the stacklight to communicate on EtherNet/IP, Millennium Controls suggested HMS’s EtherNet/IP Linking Device, which acts as a translator between the stacklight and the PLC enabling them to communicate. The EtherNet/IP Linking Devices have a unique integration to Studio 5000 Logix designer, allowing for quick and easy connectivity to Modbus-TCP devices. Anybus gateways from HMS can also be used to connect the entire machine to another industrial network like ModbusTCP, EtherCAT or PROFINET, if it needs to communicate in a non-Rockwell environment

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.