Published on 01/16/2017 | Market Sizing

IT DOESN’T take long to walk from Siemens’s old headquarters in Munich to its new one, inaugurated in June: the German industrial conglomerate has built it right next door. The design is cutting-edge, as are the building’s environmental features. It is packed with energy-saving sensors; channelled rainwater is used to flush the toilets.

General Electric, Siemens’s big American rival, will soon have a new base, too. But it takes three hours to drive from the old site in Fairfield, a Connecticut suburb, to the new one in Boston. Its building will also boast plenty of green technology, such as a huge canopy made of solar panels, as well as spaces that the public can enter, including co-working areas and lounges. There will be laboratories both for internal startups and some from outside.

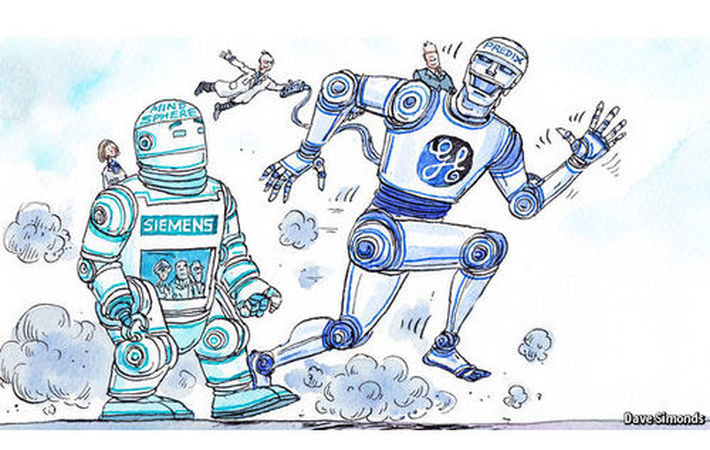

The two industrial giants aren’t so much showing off as signalling transformation. Both firms are going through the most profound change in their corporate histories, attempting to switch from being makers of machines into fully digital businesses. GE’s chief executive, Jeff Immelt, says the plan is to join the world’s top ten software firms with sales of programs and services worth $15bn as early as 2020.

It is tempting to bracket the firms together for other reasons, too. The basic numbers make them look alike. With annual revenues of around $100bn each, they are the world’s two largest diversified industrial conglomerates. About 70% of their markets overlap with each other, reckons J.P. Morgan, a bank.

But the similarities only go so far. GE mostly sells big, stand-alone products, such as jet engines and locomotives. It may look like a collection of distinct divisions, but it has a strong centre and can move swiftly. It is also greatly influenced by America’s technology giants.

Siemens, in contrast, excels in product design and factory automation. It already has experience in digitising the entire life cycle of an industrial product, from design to fabrication, so it is in some ways already more of an IT firm than GE (though it still has a very long way to go). The German firm is more decentralised, featuring competing centres of power. Its top managers prefer to weigh options carefully, not always with great results: Siemens is about half as profitable as the American firm.

It is no surprise, then, that the two firms are also taking very different paths towards digitisation. GE is completely reinventing itself, whereas Siemens is staying close to its roots. What works best will be closely watched by other companies in all sorts of industries. They want to know what happens when operating technology, as represented by GE and Siemens, properly meets information technology. The first tends to be organised in vertical, industry-specific silos, such as machine tools and medical equipment. The second typically comes in horizontal, widely used layers, such as computer operating systems. Bringing it all together could go badly wrong.

Data have long been crucial for manufacturing and industrial goods. Siemens digitises its customers’ factories; a typical GE jet engine contains hundreds of sensors. But now the data are no longer binned when the widget comes out of the factory or the plane has landed. Thanks to faster internet connections, cloud computing and clever algorithms, information can now be easily collected, stored in huge “data lakes” and sifted for insights.

That technology allows manufacturers to create what David Gelernter, a pioneering computer scientist at Yale University, over two decades ago imagined as “mirror worlds”. GE wants to build a similar, “virtual twin” of every category of physical asset it sells, from locomotives to wind farms. This would allow engineers to test products before they are built and also let them feed the virtual model with real-world data to improve performance. “A digital twin is not just a generic model but based on the exact conditions in the real world,” explains Ganesh Bell, chief digital officer at GE Power.

Although the efficiency gains for a single product may be relatively small, they can add up to billions of dollars in savings for customers over the lifetime of equipment. More broadly, linking the physical and the digital worlds via the “internet of things” (IoT) could create up to $11trn in economic value annually by 2025, estimates the McKinsey Global Institute, a think-tank. A third of that could be in manufacturing.

It is not just the promise of such gains, however, that has prompted Siemens and GE to overhaul themselves. Digitisation is also a threat. If they do not satisfy customers’ demands to replace machines less often and to spend less money on maintenance, others will. Big IT firms such as Google and IBM might come to control the virtual part of manufacturing by developing software and services to optimise factories and supply chains. That would slice off a big chunk of manufacturers’ profits.

GE’s answer has been to invest billions since 2011 in a data platform called Predix. It wants the system to become for machines what Android is for smartphones: the dominant host of industrial “apps” to manage, for example, clusters of wind turbines and fleets of locomotives. GE has set up Predix to be “open”, meaning that it doesn’t only work with its own machines or its own apps. For example, Pitney Bowes, a maker of heavy-duty mailing systems and products, uses the platform to analyse data from its machines in order to manage them better.

GE is also using Predix as a way to shake up its internal organisation. It set up a separate software unit in San Ramon, near Silicon Valley, to develop it. “We incubated the unit separately because it would otherwise have been killed by the main organisation,” explains Bill Ruh, who heads GE Digital. Only in September last year did it merge the startup with the company’s other digital activities, including its entire IT department, to form Mr Ruh’s unit. It interacts with all other GE businesses, making sure that an algorithm to control electric motors in a locomotive, say, can also be used for similar devices in a wind turbine or a power plant.

GE is changing its culture in other ways, too. As an industrial conglomerate, the firm was known for its near-obsession with the Six Sigma management method. This uses statistics and incremental improvements to drive everything a company does close to perfection. Now GE wants workers to take a leaf from the world of startups and start making mistakes—an approach it is calling “FastWorks”. The idea is to experiment more and to develop so-called minimum viable products that can be discarded quickly if they fail to take off.

Siemens’s digital transformation appears to be going more slowly (although that may be partly because its managers are less vocal about the firm’s achievements). Its primary focus is still on software tailored to industry verticals, such as health care and manufacturing, rather than on a horizontal platform to fit all sectors. Only recently did it begin marketing MindSphere, its equivalent to Predix, more intensively. “Our customers live in worlds that are very different from each other,” explains Horst Kayser, the firm’s head of strategy. Siemens is also keen not to displease an important group of customers: machine-tool makers that use components from Siemens. They want to maintain direct relationships with their own industrial customers, not have them interacting through a platform like MindSphere.

Because MindSphere is less important inside Siemens than Predix within GE, the German firm’s organisational changes have so far been less radical. But it is trying to open itself up to ideas from outside. Internal startups used to be at the mercy of its budgeting process, which often meant that they were the first to lose funding. In June the firm created a separate home for such projects, called next47 (Siemens was founded in 1847 in a Berlin courtyard), which is part-incubator, part-investment firm. It has hired an American to run it, but rather than basing it in the German capital, which boasts a thriving startup ecosystem, it will remain in Munich.

Siemens has also started sending senior employees on so-called “learning expeditions” to startups to see how things can be done differently. Its employees are now encouraged to communicate across organisational boundaries and directly with bosses. The company would have to do much of this regardless of its priorities in the digital sphere; a reputation for being risk-averse and overly hierarchical is not the best way to attract young talent as Germany’s population ages.

In other IT markets, one firm has quickly come to dominate, whether in online search (Google), computer operating systems (Microsoft) or corporate databases (Oracle). That seems to argue in favour of a gung-ho approach. GE is already well on its way to creating an “ecosystem” for Predix, says Nicholas Heymann of William Blair, an investment bank. It has agreed partnerships with big telecoms operators, consultancies and IT-services companies, not least to gain access to outside data sources.

Yet the consumer world and that of business differ. Online search and social-networking services are easy to scale, because human beings’ needs are similar across the world. Particular industries and companies, on the other hand, often have specific requirements that call for customised products—not for a platform that is trying to be all things to all machines. That may help Siemens’s more tailored, customer-centric approach.

Siemens’s attitude to its industrial customers’ data may also work better than GE’s. Whereas individual consumers are by and large willing to give up personal information to one platform, such as Google or Facebook, most companies try to avoid such lock-in. Whether they are makers of machine tools or operators of a factory, they jealously guard their data because they know how much they are worth. Both GE and Siemens say their customers will keep control of their data in the new digitised world, but the real question is who will own the algorithms that are generated using these data. GE claims ownership, Siemens is much less categorical.

It is thus unlikely that a single platform will come to dominate the industrial internet. There will be plenty of room for Predix, MindSphere and other services, concludes Andreas Willi of J.P. Morgan. Nonetheless GE seems better prepared for a digital future. The firm now has a flexible organisation that can change course quickly. Siemens, by contrast, is still living in a more closed vertical world. Both new headquarters feature small museums displaying the firms’ roots. No prize for guessing which one you can visit strictly by appointment only.

You can find the full article on The Economist here.