Published on 12/06/2016 | Use Cases

The idea of implementing sensors in concrete structures is not new. Various types of technologies have been developed over the past 20 years to monitor the performance of concrete materials and structures. These include the measurements related to mechanical properties such as stress, strain and vibration as well as changes in materials characteristics such as temperature and humidity, and even monitoring the chloride penetration and corrosion of rebar in concrete. But, the challenge has been always about the analysis of the collected data and a closed-loop integration of the results in order to optimize various processes during early-age construction and later while in service.

With the recent advancements in the IoT domain including the development of smart wireless sensors, mobile apps, and cloud-based solutions, it is expected to experience a major improvement in the capability of the sensor-based technologies that have been already developed and used in the construction sector. Giatec is a knowledge-based company that has been working over the past few years on wireless and mobile-based concrete testing technologies for various application. But, with the recent announcement of Smart Concrete™, Giatec is bringing a complete IoT package to the concrete industry.

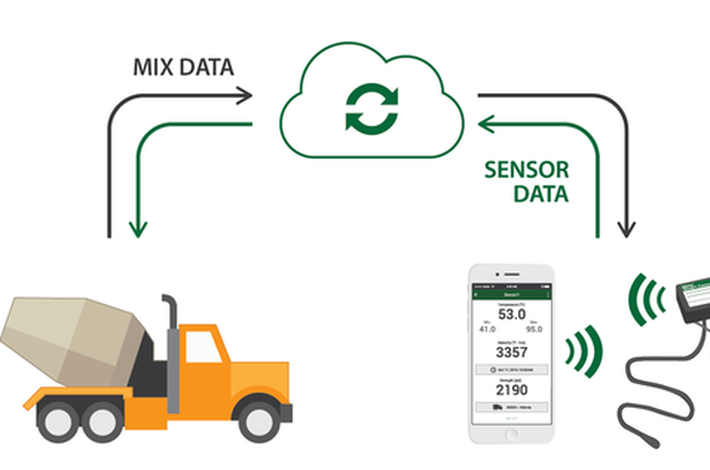

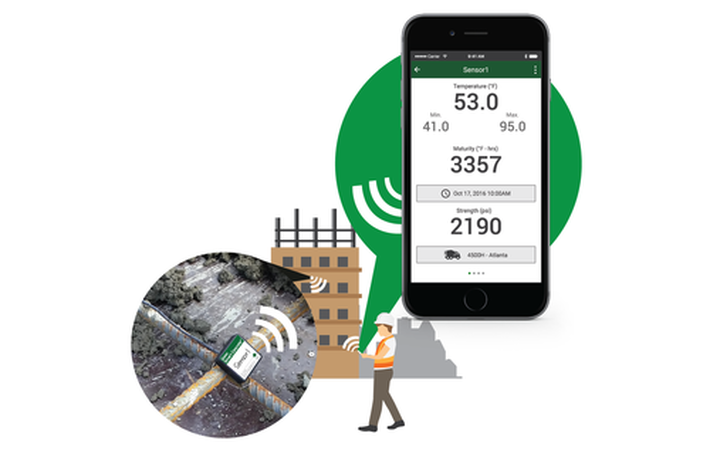

Smart Concrete™ is a value-added solution that enables ready-mix producers to monetize their proprietary data on concrete materials while improving the speed and efficiency for contractors on the job-site. Through this system, ready-mix producers can upload a list of calibrated Smart™ mixes on the cloud. Then, they will provide smart sensors to contractors who want to obtain real-time concrete strength on the job-site. This is critical information for them as various construction operations such as formwork removal and post-tensioning can not be initiated unless a specific strength is met for concrete as it sets and hardens during the first few days after placement. Contractors only need to install these smart sensors in the concrete during the placement, and use the Smart Concrete™ app (on iOS or Android) to assign the producer's concrete mix they are using to that sensor. The propriety calibration data is automatically synced from the cloud to the sensor and contractor will then be able to see the strength of concrete on their mobile phone.

The data collected on the mobile phones is automatically backed up on the cloud. The ready-mix producer can then access the data and examine the performance of the mixes on the job-site in order to optimize the mix design for the next concrete placements. This is now possible for the first time in the concrete industry to have a closed-loop field data integration in the ready-mix process. Smart Concrete™ brings significant value to the ready-mix producers as well as contractors while helping with a better optimization of the using natural resources. In addition, Smart Concrete™ offers various layers of live data sharing, reporting, data analytics, and cloud-based features such as strength prediction. Learn more at www.smartconcrete.co.

This article was originally posted on LinkedIn.