- Automation & Control - Supervisory Control & Data Acquisition (SCADA)

- Functional Applications - Remote Monitoring & Control Systems

- Networks & Connectivity - Cellular

- Sensors - Gas Sensors

- Equipment & Machinery

- Business Operation

- Leakage & Flood Monitoring

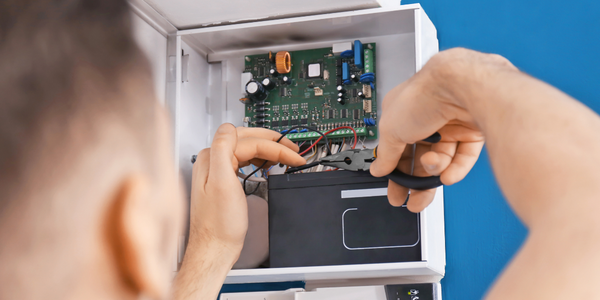

WIN-911’s partner product ALERT is a key element in the Supervisory Control and Data Acquisition (SCADA) system “FabView” from Air Liquide. Air Liquide is the second largest supplier of industrial gasses in the world. This SCADA alarm notification system is specifically designed to monitor, among other things, the distribution of gas in a semiconductor manufacturing plant located in Dresden Germany. Like most operations of its type, this facility can’t afford much downtime in its distribution facility. If ALERT detects a leak in a pipeline, the system evaluates how severe the leak is and transfers the data back to the central site or home office. Once the information is back in the main office, the SCADA alert system then transcribes the data into understandable messages to which employees can respond appropriately.

SCADA alarm notification

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.