- Functional Applications - Remote Monitoring & Control Systems

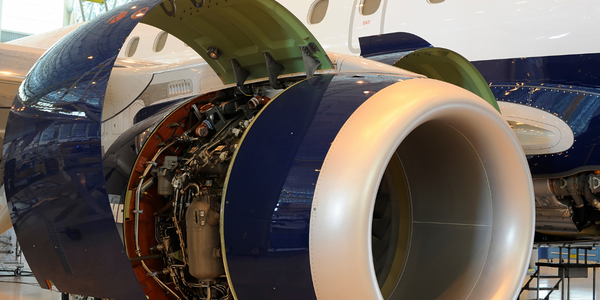

- Aerospace

- Discrete Manufacturing

- Process Control & Optimization

When UTC Aerospace required a solution to manage assembly line workers with no previous manufacturing experience, it decided to try something new that set a precedent for its future manufacturing operations management (MOM) strategy.

Using manufacturing software from PINpoint Information Systems that features situational awareness graphics on plant floor touchscreens, the manufacturer was able to train an unskilled workforce to build safety critical electronics without defects, which actually helped ramp up production within days, said UTC Aerospace. With the software monitoring and controlling the hundreds of process steps needed to build the products, problems and defects could not go unchecked so error-proofing was maximized.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.