Werma

Overview

|

HQ Location

Germany

|

Year Founded

1950

|

Company Type

Private

|

Revenue

$100m-1b

|

|

Employees

201 - 1,000

|

Website

|

Twitter Handle

|

Company Description

Clever solutions that simply work – this has been our goal at WERMA for decades, and customers from all over the world confirm our success day after day. We are setting the standards for modern signal technology - and are also defining their future: for more than twenty years with modular signal towers as the industry standard, and with networked, intelligent system solutions today.

The "Made in Germany" label is thereby a guarantee that now allows us to describe ourselves with pride as "Europe's leading signal" .

This account is updated by WERMA (Shanghai) Co., Ltd.

The "Made in Germany" label is thereby a guarantee that now allows us to describe ourselves with pride as "Europe's leading signal" .

This account is updated by WERMA (Shanghai) Co., Ltd.

IoT Solutions

WERMA’s SmartMONITOR helps to make processers lean, faster and more efficient. The wireless based data collection and transmission system is easy to retrofit and enables analysis of the operation which in turn will lead to untapping growth potential and keeping you one step ahead of the competition.

Learn more about WERMA' SmartMONITOR system: werma.wistia.com/medias/c9i502vem4

Learn more about WERMA' SmartMONITOR system: werma.wistia.com/medias/c9i502vem4

IoT Snapshot

[Vendor_Name] is active in the automotive industries.

Use Cases

Functional Areas

Industries

Supplier missing?

Start adding your own!

Register with your work email and create a new supplier profile for your business.

Case Studies.

Case Study

Call for action immediately in Siemens

In line with their Industry 4.0 development initiative, the Siemens factory in Nanjing felt that using phone calls as the primary method for reporting and calling for action was not acceptable for long-term development goals. In addition, phone calls do not create any data that can be stored for future referencing.

Case Study

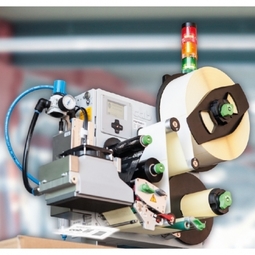

"cab" Selects Signal Towers from WERMA

Clearly identifiable labelling and product marking is an essential part of any business whether it is on individual components, finished products or packaging. Europe's largest manufacturer of labelling and printing machines, supports its reputation for innovation, reliability and durability by the careful selection of essential bought in components for its own operation. This is why cab selected the new innovative modular signal tower series KombiSIGN 40 from WERMA.

Similar Suppliers.

Supplier

congatec AG

congatec AG offers a product portfolio that is comprised of embedded computer modules based on the most common form factors such as Qseven, COM Express and ETX/XTX. congatec also provides professional board support packages, extensive design-in support and specialized embedded BIOS features for industrial use.

Supplier

Quant Service

Quant Service is a global leader in industrial maintenance. For over 25 years, we have been realizing the full potential of maintenance for our customers. From embedding superior safety practices and building a true maintenance culture, to optimizing maintenance cost and improving plant performance, our people make the difference.

Supplier

Princeps

PRINCEPS is an R&D intensive company. We have conducted a significant R&D effort in cooperation with academic organisations in Europe (PRINCEPS is the initiator and coordinator of several EU funded projects).Strong with more than 15 years field experience through planning and scheduling projects worldwide, we have developed an innovative software suite which introduces a new paradigm in this domain.Most importantly, PRINCEPS has developed over the years, a strong working partnership with its clients, which is at the foundation of its customer oriented culture.The Oil industry is one of the pioneers in the widespread adoption of optimization techniques. The term “Refinery optimization” has consequently evolved to become a multi-faceted concept.At an abstract level, refinery optimization is about getting the most from the existing assets; by extension, it can also refer to the most profitable investments in new equipment or new assets. This first distinction gives rise to 2 horizons of application to refinery optimization: long term, structural optimization, and short term operations optimization. Moreover, operations management itself can be addressed in a variety of ways, depending on whether the approach taken to refinery optimization is bottom-up, or top-down:The top-down approach is based on hierarchical optimization: the refinery optimization problem is addressed as a succession of optimization problems of different time magnitudes and granularities. The first problem is a mid-term planning problem and is concerned with the refinery as a whole and a time frame of one to several months. Subsequently, the time frame is subdivided into finer time intervals. At the lowest level, the theoretical goal is to achieve operations scheduling on a day to day basis.The bottom-up approach is one that starts with local problems and tries to aggregate them into a consistent solution at the refinery level.In contrast to traditional bottom-up approaches – which attempt to build an overall solution by aggregating local solutions – we start by achieving a feasible, “good quality” overall solution using our smart simulation engine. Then, guided by the consistent overall solution, we seek to optimize local operational challenges.Our innovative approach to refinery optimization takes account of 2 crucial facts:- Day-to-day operations are subject to uncertainty,- Regardless of the inherent formal difficulty of achieving an overall refinery schedule optimization, an overall optimized schedule is of little use.This is simply because an overall solution achieved that way is inherently unstable: the slightest change or unforeseen event means that the whole schedule must be rebuilt. And given the huge amount of inertia in such a large system, any sudden change of trajectory consumes an equally huge amount of energy.Under this pragmatic perspective, refinery optimization appears as the search for a maintainable globally feasible, locally optimized schedule. Optimization is applied to sub-systems where a high economic impact is achievable.

Supplier

Flexis

flexis is a software supplier and consulting firm providing cutting edge solutions for a multitude of production markets. With deep industry expertise, innovative in memory technology, and proven solution frameworks, flexis is able to provide user friendly, fast and reliable solutions. These solutions can be used together with MES and ERP Systems for SOP, APS and SCM. flexis solutions are used by over 250 customers in 25 countries and have a proven track record to improve operations for sales, manufacturing and supply chain business processes and increase overall business efficiency. Company locations: Germany, USA, Canada, Japan, China

Supplier

KEBA

Founded in Linz in 1968, KEBA today is an internationally active company that creates its success from technological innovations, the highest quality requirements, and the dynamism and enthusiasm of its employees. KEBA works on new developments and industry solutions with the objective of creating sustainable competitive advantages for its customers.The headquarters are in Linz, Austria. KEBA AG is represented by subsidiaries around the world. Part of the KEBA group are also the German company KEMAS, the Dutch company DELEM and the Chinese joint venture CBPM-KEBA. In the fiscal year recently concluded (as of 03/31/2017) sales of € 193 million were earned.