Technology Category

- Functional Applications - Inventory Management Systems

- Functional Applications - Manufacturing Execution Systems (MES)

Applicable Industries

- Aerospace

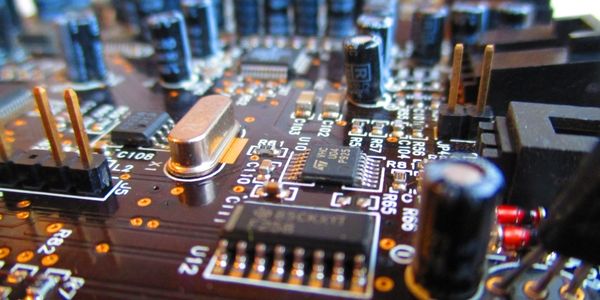

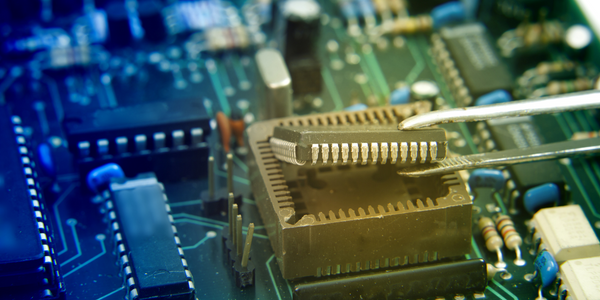

- Electronics

Applicable Functions

- Logistics & Transportation

- Product Research & Development

Use Cases

- Additive Manufacturing

- Supply Chain Visibility

The Customer

Kitron

About The Customer

Kitron is a leading Electronics Manufacturing Services (EMS) company with operations in Norway, Sweden, Lithuania, Germany, Poland, China, and the USA. Established in the early 1960s in Arendal, Norway, Kitron's head office is now in Asker, Norway. The company has 1700 employees deployed in six different countries in Europe, Asia, and the US. Kitron's core areas of expertise are in the sectors Defense/Aerospace, Energy/Telecoms, Industry, Medical devices, and Offshore/Marine. The company manufactures and delivers anything from fully assembled electronic circuit boards to complete end products for customers globally. Kitron is also developing expertise in Automotive Electronics with a special focus on Autonomous Technologies. The company is listed on the Oslo Stock Exchange (ticker: KIT).

The Challenge

Kitron, a leading electronics manufacturing services company, was facing challenges in maintaining its competitive edge in a rigid market. The company needed to stay up-to-date with the latest technology, robotics, automation, and digitalization. Kitron was also looking for a partner, not just an IT supplier, who could understand their industry, needs, and challenges. The company had previously used other leading industry solutions but found them too rigid. They needed a solution that could integrate with other systems. Kitron also had high growth targets, aiming for a 30% increase in revenue. As the company worked with high complexity products with low volume production, this translated into a focus on supply chain, flexibility to change, security, and efficiency. The company also needed to find the best suppliers.

The Solution

Kitron partnered with IFS, replacing around 50 individual systems with IFS Applications. This partnership was not just about software provision, but also about influencing the direction of future solutions. After standardizing their operations around IFS in 2009, Kitron set up a Solution Competence Centre to assure results and continuous improvements. IFS's strategic decision to create a partner network solved much of their capacity challenges. Kitron is now using IFS for supply chain, integrations, configurations, and demand-driven material requirement planning (MRP), which has the potential to reduce inventory by 40 percent and lead times by 80 percent. MRP enables the manufacturers to access an interface of their current parts and see the parts highlighted in red that need to be reordered, resulting in a more agile supply chain management. Kitron also invested in four new ABB Yumy automated robots for their Swedish factory, in addition to their autonomous production line in Lithuania.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

Remote Temperature Monitoring of Perishable Goods Saves Money

RMONI was facing temperature monitoring challenges in a cold chain business. A cold chain must be established and maintained to ensure goods have been properly refrigerated during every step of the process, making temperature monitoring a critical business function. Manual registration practice can be very costly, labor intensive and prone to mistakes.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.