- Analytics & Modeling - Computer Vision Software

- Consumer Goods

- Discrete Manufacturing

- Computer Vision

- System Integration

BSH Home Appliance Group

BSH Home Appliance Group is a global manufacturer of household appliances. They are known for producing a variety of products including ovens, refrigerators, dishwashers, and washing machines. The company was founded in Germany and currently operates in over 50 countries worldwide. BSH has been in operation for more than 100 years, they have an emphasis on innovation and technology, providing products that meet the changing needs of their customers. They also have a reputation for manufacturing excellence and focus on sustainability.

QA automation is a cost-effective solution for manufacturers, as it saves time and money while reducing the risk of defective products. However, traditional QA methods are not sufficient for meeting the rigorous standards of Industry 4.0, and traditional machine vision solutions can be expensive and difficult to implement. BSH, a manufacturer of home appliances, faced this challenge and sought to improve the accuracy and efficiency of their batch inspection process without incurring high costs. They partnered with Inspekto to address the issue and reduce detection time of component defects at one of their oven manufacturing plants in Germany.

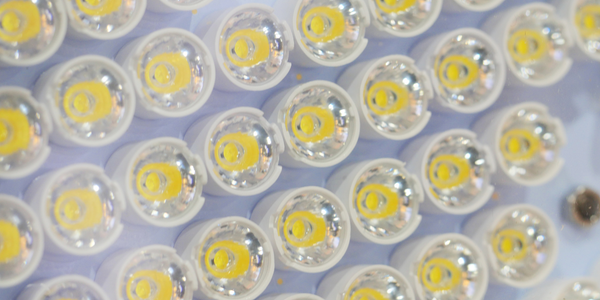

Inspekto has developed a new approach to industrial QA called Autonomous Machine Vision (AMV) that combines the capabilities of human vision with the reliability and repeatability of industrial machine vision. AMV systems are pre-trained for a wide range of use cases, making them easy to install and deploy independently in a short amount of time. The system uses artificial intelligence (AI) to automatically adjust image capturing parameters, such as distance, lighting, and exposure, allowing users to simply present the system with 20-30 sample items for it to learn and flag any deviations from the standards. This user-friendly approach is made possible through Inspekto's proprietary technology, AMV-AI, which combines three AI modules to mimic the human cognitive vision process from start to finish. BSH, a manufacturer of home appliances, was impressed by the user-friendliness and accuracy of the technology, and implemented Inspekto's S70 AMV system at their plant in Traunreut, Germany.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

.png)