Search Result.

Case Studies

56

|

UAV for Construction Sites

The Swiss power company Axpo is building a new, underground pumped storage plant – the largest in the country – in the Canton of Glarus. In the future, the plant will guarantee the future electricity supply to northeastern and central Switzerland. The plan is for the plant to pump water from Lake Limmernsee back up to Lake Muttsee – an altitude difference of 630 metres – where it can be used again to generate electricity when required. This large-scale project, which involves investment costs of around 1.7 billion euros and is expected to take the best part of five years to complete, will employ up to 500 people at various construction sites. The plant should start to deliver electricity in 2015/2016. Hundreds of thousands of cubic metres of soil and rock will have to be removed to build the tunnels and caverns for the pumped storage plant. Most of this spoil will be transported to the Muttenalp mountain by cable car and used to build the dam, which will be more than a kilometre long and rise to a maximum height of 36 metres. The rest of the material will be deposited in front of the existing Limmern dam. The company needs to survey the surrounding before implementing the project. |

|

Transforming design and construction.

Trimble needs a solution to enable better collaboration and communication between coworkers remotely, instead of using paper / 2D to communicate with each other about 3D designs. |

|

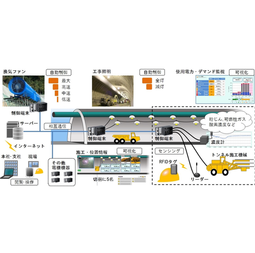

IoT System for Tunnel Construction

The Zenitaka Corporation ('Zenitaka') has two major business areas: its architectural business focuses on structures such as government buildings, office buildings, and commercial facilities, while its civil engineering business is targeted at structures such as tunnels, bridges and dams. Within these areas, there presented two issues that have always persisted in regard to the construction of mountain tunnels. These issues are 'improving safety" and "reducing energy consumption". Mountain tunnels construction requires a massive amount of electricity. This is because there are many kinds of electrical equipment being used day and night, including construction machinery, construction lighting, and ventilating fan. Despite this, the amount of power consumption is generally not tightly managed. In many cases, the exact amount of power consumption is only ascertained when the bill from the power company becomes available. Sometimes, corporations install demand-monitoring equipment to help curb the maximum power demanded. However, even in these cases, the devices only allow the total volume of power consumption to be ascertained, or they may issue warnings to prevent the contracted volume of power from being exceeded. In order to tackle the issue of reducing power consumption, it was first necessary to obtain an accurate breakdown of how much power was being used in each particular area. In other words, we needed to be able to visualize the amount of power being consumed. Safety, was also not being managed very rigorously. Even now, tunnel construction sites often use a 'name label' system for managing entry into the work site. Specifically, red labels with white reverse sides that bear the workers' names on both sides are displayed at the tunnel work site entrance. The workers themselves then flip the name label to the appropriate side when entering or exiting from the work site to indicate whether or not they are working inside the tunnel at any given time. If a worker forgets to flip his or her name label when entering or exiting from the tunnel, management cannot be performed effectively. In order to tackle the challenges mentioned above, Zenitaka decided to build a system that could improve the safety of tunnel construction as well as reduce the amount of power consumed. In other words, this new system would facilitate a clear picture of which workers were working in each location at the mountain tunnel construction site, as well as which processes were being carried out at those respective locations at any given time. The system would maintain the safety of all workers while also carefully controlling the electrical equipment to reduce unnecessary power consumption. Having decided on the concept, our next concern was whether there existed any kind of robust hardware that would not break down at the construction work site, that could move freely in response to changes in the working environment, and that could accurately detect workers and vehicles using radio frequency identification (RFID). Given that this system would involve many components that were new to Zenitaka, we decided to enlist the cooperation of E.I.Sol Co., Ltd. ('E.I.Sol') as our joint development partner, as they had provided us with a highly practical proposal. |

Suppliers

2

|

ZPMC (China Communications Construction)

Shanghai Zhenhua Heavy Industries Co., Ltd. (ZPMC) is a state-owned heavy-duty equipment manufacturer listed on A and B shares on Shanghai Stock Exchange.ZPMC has 10 production bases located in Shanghai, Nantong with total area of 6,670,000 square meters and 10 kilometers coastline, especially the Changxing Base, which has a 5 kilometers deep water coastline, and includes a heavy-duty dock of 3.7 kilometers.ZPMC is the largest port machinery heavy-duty equipment manufacturer in the world and owns a fleet of 25 transportation ships which are from 60,000 DWT to 100,000 DWT can deliver products all over the world. |

|

China Communications Construction

China Communications Construction Company Limited (“CCCC”), initiated and founded by China Communications Construction Group (“CCCG”), was incorporated on 8 October 2006. Its H shares were listed on the Main Board of Hong Kong Stock Exchange with stock code of 1800.HK on 15 December 2006. The Company (including all of its subsidiaries except where the content otherwise requires) is the ?rst large state-owned transportation infrastructure group entering the overseas capital market. As at 31 December 2009, CCCC has 112,719 employees and total asset of RMB267,900 million (in accordance with PRC GAAP). Among 127 central enterprises governed by SASAC, CCCC ranked No.12 in revenue and No.14 in profit for the year. |

Use Cases

2

|

Construction Management

Construction management includes a range of solutions to support the planning and execution of construction projects. This use case is often supported by a smart construction site platform that manages human, machine, material, process, and environmental resources to enable data-driven decision making. These systems improve coordination efforts between teams and across sites and streamlines internal communications. Data is collected from a diverse array of sensors, cameras, equipment, and manual entry points. Data is then transmitted to the cloud via multiple communication protocols such as 3G/4G/5G, WIFI, or LoRAWAN. A centralized cloud-based platform provides data aggregation, analysis, and utilization. Applications provide management visibility into site management conditions (assets status, pollution, project management, etc.). Solutions may also include operation-level monitoring of construction progress using image-based 3D point clouds and 4D Building Information Models (BIM). |

|

Construction Site Monitoring

Construction site monitoring uses IoT-enabled devices and sensors to collect data at construction job site in order to track progress remotely. IoT enabled equipment tracking allows construction companies to manage utilization, control costs and make smarter equipment decisions. Site monitoring sensors are primarily used to monitor enclosed areas in vertical construction, while concrete sensors are common in horizontal construction. Construction site monitoring is also the most common use for drones on active sites. Drone scans enable site managers to obtain high-resolution photography and video remotely, allowing them to “be on-site” even when schedules prohibit. High-resolution photographs and videos are transmitted to the construction management team via SaaS solutions that support identification and tracking of project status and potential issues. |