Digital Twin

Overview

The digital twin is a digital replica of a living or non-living physical entity. Digital twin refers to a digital replica of potential and actual physical assets (physical twin), processes, people, places, systems and devices that can be used for various purposes. The digital representation provides both the elements and the dynamics of how an object operates throughout its lifecycle. Definitions of digital twin technology emphasize two important characteristics. Firstly, each definition emphasizes the connection between the physical model and the corresponding virtual model. Secondly, this connection is established by generating real-time data using sensors to provide an evolving perspective into the current status of the physical object. The concept of the digital twin can be compared to other concepts such as cross-reality environments or co-spaces and mirror models, which aim to, by and large, synchronise part of the physical world with its cyber representation.

Case Studies.

Case Study

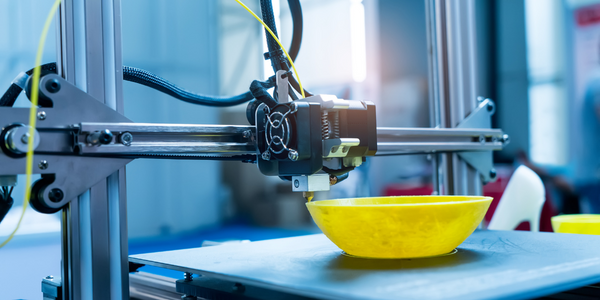

Intralox Using Demo3D Case Study

Intralox strives to create significant economic value for our customers by optimizing their conveyance systems. Intralox wants to emulate real-world production environments for end users and OEMs working in multiple industries, including packaging, warehousing, parcel, beverage, brewery, food, tire, and consumer goods. They frequently had to perform physical tests to demonstrate to customers how ARB equipment would handle their products.

Case Study

ThyssenKrupp employs Visual Rules BRM

ThyssenKrupp Steel Europe found itself in the position of needing to replace, step by step, the models it had programmed itself to manage the production of various grades of steel with a solution equipped to face the demands of the future. The solution had to be easy to integrate and designed to be rolled out step by step. ThyssenKrupp Steel Europe uses its automation systems to manage the whole production process at its company steel plants. This is done using clever algorithms that map the functional relationships across all stages of the steel production process. However, there are still a host of other changeable factors that influence the quality of the product obtained, and these also need to be factored in in the form of rules or formulae. What ThyssenKrupp Steel Europe was looking for was a suitable piece of software to fulfill this rule-based management function.

Case Study

K-Engine's On-site Design & Cost Estimation Benefits Using AR

In the housing industry, around 60,000 small to midsize housing builders are creating images and calculating the estimated cost of each project based on the requirements of home owners. Due to the huge selection of products and options, it usually takes around one week and cost for users to create images using CAD tools in addition to picking out products from multiple vendor product catalogs.