Overview | ||||||

| Supplier Slogan | Predictable Reliability | Discover the Hidden Value Your Machines Can Reveal | insmart | The first end-to-end digitalization platform | ||

| HQ Location | European Union | India | United States | Netherlands | Germany | Austria |

| Year Founded | 2015 | 2012 | 2015 | 2019 | 2020 | 2021 |

| Company Type | Private | Private | Private | Private | Private | Private |

| Stock Ticker | ||||||

| Revenue | < $10m | < $10m | < $10m | < $10m | < $10m | < $10m |

| Employees | 11 - 50 | 11 - 50 | 11 - 50 | < 10 | 11 - 50 | < 10 |

| Website | Open website | Open website | Open website | Open website | Open website | Open website |

| Company Description | Passionate about solving the problem of unplanned downtime, Semiotic Labs uses advanced AI and Machine Learning technology to create smart condition monitoring products that increase productivity while saving clients’ time and money. | Algo Engines helps provide operating intelligence for the met masts, wind turbines, solar plants and other IoT systems. They have developed cloud-based SaaS platform for Internet of Things (IoT) Analystics. The other solutions are based on SCADA systems, sensors and Smart Meters. | We understand industrial equipment manufacturing because we have lived it for over 30 years. Elevāt was born out of a 30-year leader in heavy equipment supply and integration. Before Elevāt existed, we were receiving requests for guidance on how to proceed with IoT and Digitization initiatives from our customers. It soon became clear that the solutions available were not built to fit into existing OEM processes, were complicated to use, were difficult and time-consuming to implement and the information delivered didn’t help improve business processes. So, elevāt was incubated within the walls of an industrial manufacturing and integration company and rolled out as its own entity in 2016. | Builds solutions to monitor HVAC devices for installation companies. |

weeve is a high-tech IoT startup empowering companies to generate value from their connected assets through data-driven services. Our platform offers an intuitive way to create and customise data pipelines and processes using a simple drag and drop method. We offer a library of ready-made modules built around common use cases, such as; Predictive Maintenance, pay-per-use and Machine Learning while offering the flexibility to adapt and create new modules for your specific business domain. Our solution reduces the time needed to generate ROI from your IoT projects and delivers key business insights that can help companies optimize processes, reduce costs, improve decision making and create new revenue streams. We operate across diverse industry verticals such as Manufacturing, Energy, Automotive, Healthcare, Supply Chain, Mobility and Logistics. | We raise the value of your machines through your digital customer platform and smart services. Autonoma helps industrial machinery- and plant building manufacturers to fully digitalize their machines. Customers can collect and visualize all data easily, and build smart services on top of them, such as the Predictive Maintenance and a digital representation of their machines. With our white labelled platform, they can sell their customers a branded interface with their design to deepen their customer relationship and engagement. As a result, customers can generate service revenues with new and retrofitted machines within weeks. |

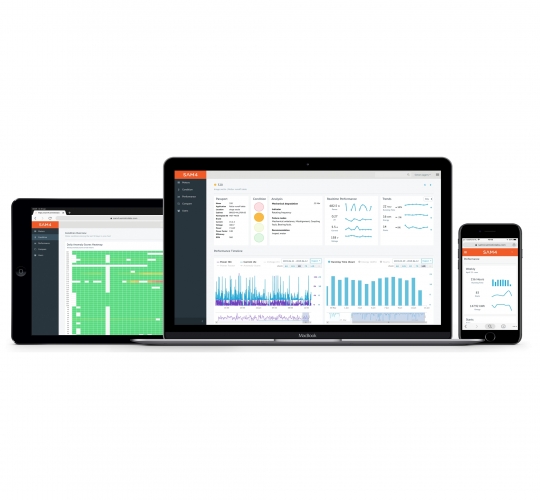

| IoT Solutions | SAM4 is a smart condition monitoring solution for AC motors and rotating equipment that installs inside the motor control cabinet and not on the asset in the field. SAM4 monitors equipment 24/7 and detects upcoming failures up to months in advance. SAM4 is an advanced IoT solution composed of sensors, analytics and an online dashboard that offers actionable real-time insights into the health, performance and energy consumption of connected assets. SAM4 is available as a scalable subscription service.

SAM4 IS AVAILABLE FOR:

| Algo Engines can work with any combination of operational turbines, farms and portfolios. It gives owners and operators uniform access to capture and analysis of their critical data. Our 3D visualization helps remote wind farm monitoring teams get a feel of the site and its terrain. We identify “at-risk” components based on a robust notification engine through Data Mining of SCADA and event data. This facilitates intelligent operational decisions, therefore maximising generation rather than just turbine availability.

Algo Engines can work with any combination of modules, inverters and sub stations. It gives owners and operators uniform access to capture and analysis of their critical data. We aim to use data to identify “at-risk” components in advance and increase generation through Data Mining of SCADA and event data. This facilitates intelligent operational decisions, therefore maximising generation rather than just availability."

| Elevāt Predictive Maintenance can be customized based on the business processes you and your customers already use. The Machine Data you are already Tracking with elevāt Industrial IoT is used to create use-based parts replacement protocols. Your services and aftermarket parts businesses grow, while eliminating unnecessary emails, phone calls, CRM and ERP updates and manual maintenance scheduling. With elevāt Industrial IoT you will know what replacement parts are needed before an asset fails, proactively help your customers increase their output and make advancements in your technology that will deliver more value with time. This turnkey application automates complex, manual processes associated with monitoring and managing everyday servicing of your accounts and their equipment assets. It turns spreadsheets, emails and phone calls into one centralized system that improves customer service. |

| We provide an edge device (and software library) to easily read and write on machine- and plant Controller to collect data. The data is visualized in the Autonoma platform, which can be branded with the customers logo and corporate design. The result is a fully scalable customer portal where industrial companies can build smart services on top, to generate more revenue. Additionally, customers can add metadata (documentations, service contracts, sales contracts, contact details, etc.) to every single machine, and can upload the CAD files to easily create a digital representation of the machine, with live data (i.e. digital twin with Augmented Reality 3D model). | |

| Key Customers |

|

| Machinery- and plant building companies with < 1000 employees. | |||

| Subsidiary | ||||||

| Parent Company | ||||||

IoT Snapshot | ||||||

| Technologies | Analytics & Modeling | Analytics & ModelingInfrastructure as a Service (IaaS) | Analytics & Modeling | Analytics & ModelingPlatform as a Service (PaaS) | Infrastructure as a Service (IaaS)Platform as a Service (PaaS)Processors & Edge Intelligence | |

| Industries | Equipment & MachineryOil & GasTransportation | AutomotiveConstruction & InfrastructureEquipment & Machinery | ||||

| Use Cases | Predictive Maintenance | Predictive Maintenance | Predictive MaintenanceAsset Health Management (AHM) | Predictive Maintenance | Predictive Maintenance | Asset Lifecycle ManagementDigital TwinEdge Computing & Edge IntelligencePredictive MaintenanceRemote Asset Management |

| Functions | Discrete ManufacturingLogistics & TransportationProcess Manufacturing | |||||

| Services | System Integration | Data Science Services | Cloud Planning, Design & Implementation ServicesSoftware Design & Engineering Services | |||

Technology Stack | ||||||

| Infrastructure as a Service (IaaS) | None | None | Minor | None | None | Minor |

| Platform as a Service (PaaS) | None | None | None | None | Minor | Moderate |

| Application Infrastructure & Middleware | None | None | None | None | None | None |

| Analytics & Modeling | None | Moderate | Minor | Minor | Minor | None |

| Functional Applications | None | None | None | None | None | None |

| Cybersecurity & Privacy | None | None | None | None | None | None |

| Networks & Connectivity | None | None | None | None | None | None |

| Processors & Edge Intelligence | None | None | None | None | None | Minor |

| Sensors | None | None | None | None | None | None |

| Automation & Control | None | None | None | None | None | None |

| Robots | None | None | None | None | None | None |

| Drones | None | None | None | None | None | None |

| Wearables | None | None | None | None | None | None |

| Actuators | None | None | None | None | None | None |

| Other | None | None | None | None | None | None |

Similar Suppliers | ||||||

| Similar Suppliers | ||||||

Partners | ||||||

| Partners | NVIDIAHoneywellSchneider ElectricRockwell AutomationAmazon Web Services | ABBNI |

Overview | ||||||

| Supplier Slogan | Predictable Reliability | Discover the Hidden Value Your Machines Can Reveal | insmart | The first end-to-end digitalization platform | ||

| HQ Location | European Union | India | United States | Netherlands | Germany | Austria |

| Year Founded | 2015 | 2012 | 2015 | 2019 | 2020 | 2021 |

| Company Type | Private | Private | Private | Private | Private | Private |

| Stock Ticker | ||||||

| Revenue | < $10m | < $10m | < $10m | < $10m | < $10m | < $10m |

| Employees | 11 - 50 | 11 - 50 | 11 - 50 | < 10 | 11 - 50 | < 10 |

| Website | Open website | Open website | Open website | Open website | Open website | Open website |

| Company Description | Passionate about solving the problem of unplanned downtime, Semiotic Labs uses advanced AI and Machine Learning technology to create smart condition monitoring products that increase productivity while saving clients’ time and money. | Algo Engines helps provide operating intelligence for the met masts, wind turbines, solar plants and other IoT systems. They have developed cloud-based SaaS platform for Internet of Things (IoT) Analystics. The other solutions are based on SCADA systems, sensors and Smart Meters. | We understand industrial equipment manufacturing because we have lived it for over 30 years. Elevāt was born out of a 30-year leader in heavy equipment supply and integration. Before Elevāt existed, we were receiving requests for guidance on how to proceed with IoT and Digitization initiatives from our customers. It soon became clear that the solutions available were not built to fit into existing OEM processes, were complicated to use, were difficult and time-consuming to implement and the information delivered didn’t help improve business processes. So, elevāt was incubated within the walls of an industrial manufacturing and integration company and rolled out as its own entity in 2016. | Builds solutions to monitor HVAC devices for installation companies. |

weeve is a high-tech IoT startup empowering companies to generate value from their connected assets through data-driven services. Our platform offers an intuitive way to create and customise data pipelines and processes using a simple drag and drop method. We offer a library of ready-made modules built around common use cases, such as; Predictive Maintenance, pay-per-use and Machine Learning while offering the flexibility to adapt and create new modules for your specific business domain. Our solution reduces the time needed to generate ROI from your IoT projects and delivers key business insights that can help companies optimize processes, reduce costs, improve decision making and create new revenue streams. We operate across diverse industry verticals such as Manufacturing, Energy, Automotive, Healthcare, Supply Chain, Mobility and Logistics. | We raise the value of your machines through your digital customer platform and smart services. Autonoma helps industrial machinery- and plant building manufacturers to fully digitalize their machines. Customers can collect and visualize all data easily, and build smart services on top of them, such as the Predictive Maintenance and a digital representation of their machines. With our white labelled platform, they can sell their customers a branded interface with their design to deepen their customer relationship and engagement. As a result, customers can generate service revenues with new and retrofitted machines within weeks. |

| IoT Solutions | SAM4 is a smart condition monitoring solution for AC motors and rotating equipment that installs inside the motor control cabinet and not on the asset in the field. SAM4 monitors equipment 24/7 and detects upcoming failures up to months in advance. SAM4 is an advanced IoT solution composed of sensors, analytics and an online dashboard that offers actionable real-time insights into the health, performance and energy consumption of connected assets. SAM4 is available as a scalable subscription service.

SAM4 IS AVAILABLE FOR:

| Algo Engines can work with any combination of operational turbines, farms and portfolios. It gives owners and operators uniform access to capture and analysis of their critical data. Our 3D visualization helps remote wind farm monitoring teams get a feel of the site and its terrain. We identify “at-risk” components based on a robust notification engine through Data Mining of SCADA and event data. This facilitates intelligent operational decisions, therefore maximising generation rather than just turbine availability.

Algo Engines can work with any combination of modules, inverters and sub stations. It gives owners and operators uniform access to capture and analysis of their critical data. We aim to use data to identify “at-risk” components in advance and increase generation through Data Mining of SCADA and event data. This facilitates intelligent operational decisions, therefore maximising generation rather than just availability."

| Elevāt Predictive Maintenance can be customized based on the business processes you and your customers already use. The Machine Data you are already Tracking with elevāt Industrial IoT is used to create use-based parts replacement protocols. Your services and aftermarket parts businesses grow, while eliminating unnecessary emails, phone calls, CRM and ERP updates and manual maintenance scheduling. With elevāt Industrial IoT you will know what replacement parts are needed before an asset fails, proactively help your customers increase their output and make advancements in your technology that will deliver more value with time. This turnkey application automates complex, manual processes associated with monitoring and managing everyday servicing of your accounts and their equipment assets. It turns spreadsheets, emails and phone calls into one centralized system that improves customer service. |

| We provide an edge device (and software library) to easily read and write on machine- and plant Controller to collect data. The data is visualized in the Autonoma platform, which can be branded with the customers logo and corporate design. The result is a fully scalable customer portal where industrial companies can build smart services on top, to generate more revenue. Additionally, customers can add metadata (documentations, service contracts, sales contracts, contact details, etc.) to every single machine, and can upload the CAD files to easily create a digital representation of the machine, with live data (i.e. digital twin with Augmented Reality 3D model). | |

| Key Customers |

|

| Machinery- and plant building companies with < 1000 employees. | |||

| Subsidiary | ||||||

| Parent Company | ||||||

IoT Snapshot | ||||||

| Technologies | Analytics & Modeling | Analytics & ModelingInfrastructure as a Service (IaaS) | Analytics & Modeling | Analytics & ModelingPlatform as a Service (PaaS) | Infrastructure as a Service (IaaS)Platform as a Service (PaaS)Processors & Edge Intelligence | |

| Industries | Equipment & MachineryOil & GasTransportation | AutomotiveConstruction & InfrastructureEquipment & Machinery | ||||

| Use Cases | Predictive Maintenance | Predictive Maintenance | Predictive MaintenanceAsset Health Management (AHM) | Predictive Maintenance | Predictive Maintenance | Asset Lifecycle ManagementDigital TwinEdge Computing & Edge IntelligencePredictive MaintenanceRemote Asset Management |

| Functions | Discrete ManufacturingLogistics & TransportationProcess Manufacturing | |||||

| Services | System Integration | Data Science Services | Cloud Planning, Design & Implementation ServicesSoftware Design & Engineering Services | |||

Technology Stack | ||||||

| Infrastructure as a Service (IaaS) | None | None | Minor | None | None | Minor |

| Platform as a Service (PaaS) | None | None | None | None | Minor | Moderate |

| Application Infrastructure & Middleware | None | None | None | None | None | None |

| Analytics & Modeling | None | Moderate | Minor | Minor | Minor | None |

| Functional Applications | None | None | None | None | None | None |

| Cybersecurity & Privacy | None | None | None | None | None | None |

| Networks & Connectivity | None | None | None | None | None | None |

| Processors & Edge Intelligence | None | None | None | None | None | Minor |

| Sensors | None | None | None | None | None | None |

| Automation & Control | None | None | None | None | None | None |

| Robots | None | None | None | None | None | None |

| Drones | None | None | None | None | None | None |

| Wearables | None | None | None | None | None | None |

| Actuators | None | None | None | None | None | None |

| Other | None | None | None | None | None | None |

Similar Suppliers | ||||||

| Similar Suppliers | ||||||

Partners | ||||||

| Partners | NVIDIAHoneywellSchneider ElectricRockwell AutomationAmazon Web Services | ABBNI |