Search Result.

Case Studies

59

|

Predictive Maintenance

Our client designs, manufactures, and leases industrial equipment and provides software to remotely monitor equipment operations. They looked to Faststream Technologies to accelerate the prototyping of intelligent features in the software platform that could reduce downtime of machinery by predicting and preventing faults.Working closely with our client’s software engineering team, Faststream built a predictive analytics prototype that consists of 2 wire current sensors, an Anemometer, equipment sensor time-series data to predict and prevent machine downtime. The system alerts field teams about units at risk of faulting, so they can proactively take action before any failure. The client’s team is able to continue the work on their own, maintain the code, and conduct further experiments using the data processing pipeline and machine learning framework we created.One sensor that we used was an inertial sensor that includes a Machine Learning Core (MLC) and a Finite State Machine (FSM). A revolutionary aspect of this sensor is that it has an embedded Machine Learning Core. Our team could configure specific parameters of the decision tree with Weka, an open-source collection of machine learning algorithms. |

|

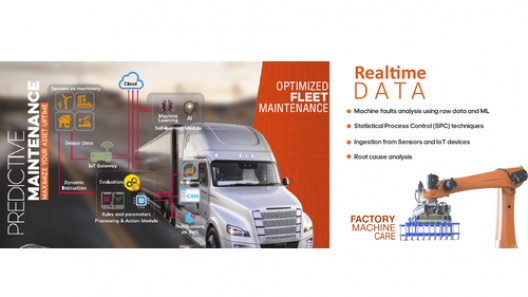

PREDICTIVE MAINTENANCE

Manufacturers rightly focus on improving profit margins and growing revenue. Attracting new customers, selling more products and lean practices can help. However, as equipment sophistication increases, so does the ability to monitor equipment. Manufacturers can now develop revenue from maintenance services. Preventive maintenance has its advantages but to really drive uptime and maintain service levels, predictive maintenance is needed. Seamless IoT and machine sensor data integration is critical as well as a low-latency messaging backbone for scalable, fast and reliable transport. Delivering potentially large quantities of data at sub-second speeds is key to downstream activities. webMethods Integration, featuring Universal Messaging, addresses this need with an enterprise-grade service bus for connectivity, messaging, transformation and security of machine data for advanced real-time analytics. |

|

Predictive Maintenance for Industrial Chillers

For global leaders in the industrial chiller manufacturing, reliability of the entire production process is of the utmost importance. Chillers are refrigeration systems that produce ice water to provide cooling for a process or industrial application. One of those leaders sought a way to respond to asset performance issues, even before they occur. The intelligence to guarantee maximum reliability of cooling devices is embedded (pre-alarming). A pre-alarming phase means that the cooling device still works, but symptoms may appear, telling manufacturers that a failure is likely to occur in the near future. Chillers who are not internet connected at that moment, provide little insight in this pre-alarming phase. |

Use Cases

4

|

Predictive Maintenance

Predictive maintenance is a technique that uses condition-monitoring sensors and machine learning or rules based algorithms to track the performance of equipment during normal operation and detect possible defects before they result in failure. Predictive maintenance enables the reduction of both schedule-based maintenance and unplanned reactive maintenance by triggering maintenance calls based on the actual status of the equipment. IoT relies on predictive maintenance sensors to capture information, make sense of it, and identify any areas that need attention. Some examples of using predictive maintenance and predictive maintenance sensors include vibration analysis, oil analysis, thermal imaging, and equipment observation. Visit our condition-based maintenance page to learn more about these methods. |

|

Predictive Replenishment

Predictive replenishment anticipates when customers will need to replenish inventory by analyzing sales forecasts and inventory levels. Typically, merchandise is sold to stores on a calendar basis or as a reaction to a purchase order, not based on actual consumption. Stores risk running out of inventory when actual consumption patterns vary from the set schedule, or they must hold excess inventory which ties up working capital. Predictive replenishment considers multiple factors such as seasonality, inventory, ordering patterns, lead time forecasts, special orders, product lifecycle phase, and service level goals, to improve replenishment forecasts for the next period. Most predictive replenishment systems are collaborative, linked with customer's demand forecasting or point of sale systems to automatically gather input into the replenishment forecasting models. Predictive replenishment can also be applied to industrial situations, such as component or raw material inventory in a factory, or spare parts inventory at a utility. |

|

Predictive Quality Analytics

Predictive quality analytics uses statistical algorithms and machine learnings to anticipate quality and safety risks before they occur, offering the opportunity to take timely and targeted countermeasures. As a first step, all available external and internal data sources are prioritized, consolidated, and correlated. Comprehensive data analyses are then performed and predictive models are developed in an iterative process, making use of a variety of evaluation techniques. Depending on the parameters which flow into the model, it is possible with these methods to forecast not only defects that appear shortly in the future but also ones which could lead to a warranty claim in the long term. The models are thus capable of integrating data sources, making efficient data mining possible and leading to user-friendly evaluations which in turn can be converted into easily readable reports for the end-user or managers at the reporting level. Wisely used, predictive quality analytics can lead to significant savings in warranty costs, improve customer satisfaction, and reduce scrap rates. |