Published on 12/19/2016 | Use Cases

If you work in the Oil & Gas industry, you’ve probably noticed that its future is being shaped around the notion of Zero Unplanned Downtime. The offshore sector, in particular, is plagued with unplanned downtime that is costing it billions in unseen value. And the problem is only going to get worse: as operating expenses are scaled down, capital projects are cut or deferred, and aging assets are operated beyond their original design life.

In response, the Oil & Gas industry has reacted by pumping a tremendous amount of money into improving operations through the Industrial Internet of Things (IIoT). Yet, this investment has not delivered fully on its promises yet. I would like to discuss below what’s still missing to make IIoT a lucrative endeavor for the Offshore operators.

But before we get to that, let’s take a look at why digitization is an indispensable part of operations in Oil & Gas.

The imperative today is lean and safe life extension of existing assets. Industry leaders are coming together to rethink maintenance processes and see if there are smarter ways to do them. They already realize that outdated technologies need replacement. They have seen the potential of connected humans, and they’re now convinced that Smart Connected Assets will transform industrial operations.

Their concerns are:

How do we predict failure of a critical asset before it fails?

How do we prioritize our maintenance needs reliably?

How do we optimize inspections, and decrease risk simultaneously ?

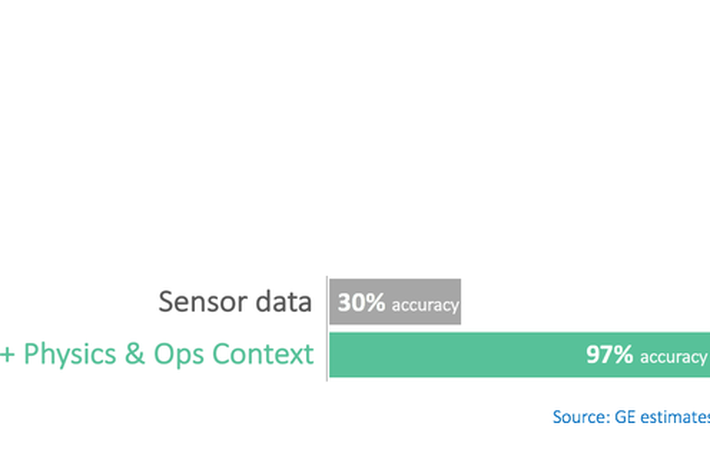

The outcome of these scenarios are benefits that Big Data promises to deliver when coupled with maintenance programs. According to GE, however, only 30% of failure modes are reliably predicted by sensors today. This means that the huge investments that were allocated to IoT in the past 5 years are still only marginally effective. In an industry where the cost of a subsea inspection, for example, can run in the millions of dollars, it is not enough to depend on sensor data to drive operational decisions.

Industry leaders and top-performing operators have realized that the digital industrial initiative is still missing a critical piece to making it reliably predictable.

The key to success in IIoT is to link together the engineer’s domain knowledge and model-centric view with the data scientist’s data-centric view. The way to do that is to combine physics-based models with Big Data analytics to create a physics-based digital twin of critical assets. A physics-based digital twin will structure the data, which in turn augments the predictive power of the Big Data framework.

According to GE, augmenting maintenance predictability of a critical asset is achieved by understanding its physics and the operational conditions that affect its performance. Physics-based models that encapsulate the operational conditions of assets will enable smart maintenance programs to reach to over 97% accuracy in predictive power.

Akselos fits perfectly in this new technology value chain and is working with leading Oil & Gas companies to meet these challenges. Leveraging next generation modeling tools based on scalable deep physics, we enable you to extract more value at lower cost:

Keep your asset up and running by using a physics-based digital twin that identifies emerging mechanical problems based on sensor data.

Equip your engineers with a holistic view of an entire asset’s condition, using an integrated software view into early-warning issues (such as increased vibration, crack propagation and more).

Identify the critical assets and the particular areas where the consequences of failure are high, using decision support tools.

Having at hand a physics-based digital twin of a critical large-scale asset, Offshore operators can focus the maintenance team’s efforts on fixing what needs repair versus having them inspect, measure, and test all critical assets on a scheduled basis. This will enable operators to leverage current IIoT investments and realize huge savings in operations and increase safety by moving from scheduled inspections to 24/7 monitoring.

As Frost and Sullivan recently noted, in a world of low oil prices, organizations must move from chasing barrels to chasing efficiency. Optimizing existing assets through a physics-based digital twin is the most effective lever to pull. It is the enlightened path to true operational excellence.