Published on 11/07/2016 | Use Cases

The way we access the Internet and the information we get from it has shifted dramatically. About 15 years ago we started using PC’s, then laptops, now we use tablets and smartphones. The majority of Internet access these days is done wirelessly.

The Internet allows us to monitor every kind of object, animal, device, machine or database. Things in our home, our workplace, our cars and trucks, and even the smallest parts of large organizations can now be monitored. Things as small as a baby’s heartbeat and as large as an aircraft carrier are being monitored by experts and decision makers.

The prices for all of this monitoring is falling quickly and many things that were too expensive last year are moderately priced today. Connections to high speed cell towers have made it easy to monitor everything that moves. Cable and satellite connections now allow HD TV to come to our homes.

Most or all of these things require radio transmission of data, voice, and video at some or many points. Making logical and economic decisions on how to connect to a vast array of operating and moving equipment is the specialty of Connexxs, LLC. The “last mile” connection is the most difficult to implement. This is where terrain, trees, radio interference, and the lack of a complete mobile network make transmission of data difficult and sometimes costly.

Remote Monitoring, Control, and Data Input allows each person to multiply their efforts without taking time to do tasks that can be assigned to Smart Machines. And because so much of today’s agricultural business is spread over large areas remote monitoring is both a time and money saver.

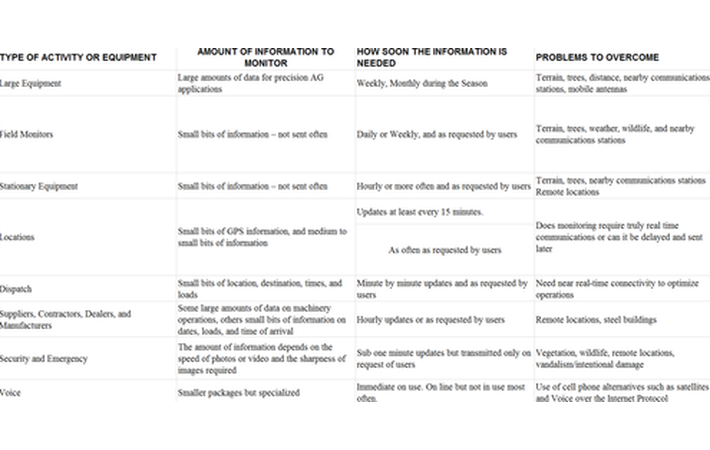

Below are several Categories of Farm Operations that can and should be remotely monitored and in some cases controlled remotely:

Large Equipment - Precisely monitored and controlled by computers in each centimeter of the field and in each row of its operations. Monitoring includes alarms on improper speed, incorrect application levels, or remaining stationary over a longer than “normal” length of time. This also includes sending and receiving the larger data files needed by growers and agronomists for recommendation/prescription and as-applied analysis.

Field monitors – Rain, soil moisture, crop health, wind, sunlight, temperature, acidity of irrigation, vegetative health, weeds, insects, etc. These can be monitored at various levels both above and below ground. Sensors are now emerging that are priced as single season, throwaway technologies that can be used throughout a farm.

Stationary Equipment – Irrigation, pumps, grain dryers, bin monitors (temperature, moisture, condition), and fuel tanks.

Location of mobile assets – People, livestock, and also the condition and location of machinery, attachments, and trucks. Location devices can be used to trigger alarms when vehicles enter or leave defined areas. They can monitor speeding and reckless driving or sudden stops including accidents. They can also monitor long stops or shut downs.

Dispatch and Logistics - Which people, machinery, trucks, trailers, are being sent to this or that location to accomplish what job? Did the person in charge acknowledge the duty and time? Are they where they were directed to be? Is the task being accomplished and if so, at what speed of delivery? Can you optimize the re-scheduling of your people and equipment when certain jobs are ahead or behind schedule?

Suppliers, Contractors, Dealers and Manufacturers – Are they responding to needs and if so, in what time period can the task be completed? Do they need to view some portion of On Farm information to better serve the farmer? What is the condition of all equipment and what preventative or predictive maintenance would keep the equipment in the best possible running order to minimize breakdowns? What inputs of seed, chemical, fertilizer, fuel, lube oil, etc. are needed?

Security and Emergency- Sensors on fences, gates, doors, panels, entrances, etc. The sensors can trigger any type of still, slow motion, and video camera. HD, long distance, night vision, license plate readers, remote control, “smart cameras” triggered by certain actions or speed. See locations for more information on operation of farm trucks and equipment. Installation of Security and Emergency equipment requires either 24 hour monitoring or an assigned protocol of law enforcement, fire, and rescue locations to notify for each alarm.

Voice - Incorporation of secure means to communicate when cell phones don’t work in many instances. This should be made a part of the integrated network on large farms.

All of these farm activities can be made a part of an integrated web portal unique for each farm that allows the owners and operators to know of problems instantly and to address them before they become larger. The role of Connexxs, LLC is to connect each of them to the Internet in the most dependable and lowest priced way that meets the needs of each customer and deliver data automatically to the MyAgCentral portal.

In simple cases such as a motor or a pump the need is simply to know if they are working as required, and perhaps at what speed or volume. In most instances the ability to remotely turn off, turn on, or adjust the speed is a very important feature.

In more complicated cases, such as a picker/combine or a tractor that pulls multiple implements the task is more difficult. Remote monitoring or sending control data in these cases requires communications with a mobile piece of equipment, sometimes in difficult terrain, and in the case of precision farming, collecting and sending very large amounts of information due to the precise nature of the requirements.

This paper will outline the best alternatives for communications with each farm component in some general categories. It will also give the reader a matrix of approximate costs for each type of remote monitoring.

All of these activities require the use of one or more radio signals that carry data, video, or voice. The amount of information in what period of time that must be transferred often decides the type of communications that are needed. In many cases factors such as distance to outside communications send/receive locations, rolling or rough terrain, tree lines, weather, and other factors influence the decisions.

Communications types for data, voice, and video are generally of three kinds: cellular, radio to radio, and satellite. In some cases radio to radio data transfers are ultimately connected either to the Internet directly or to a cellular data network or a satellite network. Radios are used to accumulate large amounts of information from many sources into one central location where it can be transmitted to end users.

Satellite dishes have become very inexpensive and easy to maintain. In some cases a satellite send/receive station is a small box with a small dome. Which satellite network to use is a specialty of Connexxs and is based on each customer’s requirements. When Connexxs has many users in several contiguous states it can keep prices of large data requirements very low. There are many things that influence use of the cell data network vs. a satellite network including cost of monthly operations and the ability to maintain constant communications.

In general equipment that requires only small amounts of information or even moderate amounts over a long time period will be much lower in cost and require less expensive and smaller devices to send and receive. Equipment that requires constant, real time monitoring of large amounts of information requires more sophisticated equipment that is more expensive and larger.

The capabilities of remote monitoring are changing rapidly. The direction we are moving is that the size of the equipment needed and the cost of the monitoring is becoming much smaller and more data can more easily be transmitted. New devices and new networks are being created almost daily.

Remote monitoring is typically charged as a one-time equipment and installation cost plus a monthly fee. The monthly fee depends upon the amount of data that needs to be transmitted and how often. Certainly more equipment being monitored in the same area from many farms also reduces the overhead of people and devices needed to control the network.

Many sensors and senders sell for around $100 with prices for larger, more sophisticated equipment selling in the $1,000 to $5,000 range. Monthly charges for monitoring can be as low as $40 to $50 and many thousands of dollars for continuous large data needs.

The real time control and maintenance of these large networks is a specialty of Connexxs. We can enable networks to monitor every type of device and our networks are designed to maintain very high levels of service.

PREPARED by Connexxs, LLC

This article was originally posted on LinkedIn.