Published on 07/06/2017 | Technology

I recently attended the Asian Downstream Week conference and exhibition, which took place in Singapore, October 26-27, is an anchor event of Singapore International Energy Week (SIEW). At the event, I had the privilege to hear from Martin Hawkins, chief operating officer from HMEL. HMEL is a joint venture between Hindustan Petroleum and Mittal Energy that has built and runs the Guru Gobind Singh Refinery in India’s northern Punjab state. I spoke with Martin about our common belief that traditional condition based maintenance and condition monitoring are still reactive maintenance and for all intensive purposes should be considered costly and maintenance performed “too late”.

In Martin’s speech, he extolled the virtues of predictive analytics. He compares this to driving a car and looking, not just over the hood, but way down the road; so you know what’s coming and can take early, appropriate action to avoid any hazards. In the plant, predictive analytics can identify those precursor events that create unsafe operating conditions, produce adverse operational consequences, and result in unexpected equipment failures. This can help produce the most valuable yields and the highest possible energy efficiency.

For the rotating machinery equipment at the Punjab facility, HMEL has evolved (and continues to evolve) its maintenance strategy, going from the stages of: Reactive (wait until a machine fails and then undertake maintenance); Preventive (perform maintenance at regular intervals, based on OEM recommendations and field observations); Condition-Based (continuously monitor the status of usually a single variable such as vibration and react to predefined thresholds and events, which is where HMEL is now); and Predictive (advanced analytics of operational and business data to predict when to perform maintenance; which is where HMEL wants to get to).

The interesting aspect of operational maintenance I share with Martin is that monitoring a single variable of an asset such as the vibration sensor on a piece of rotating equipment is still reactive. By analyzing only a few single variables, the scope of the process and its impact on an asset cannot be understood. For the process industries, assets often fail because of how they are operated.

Emerging Predictive Analytics solutions today use a bit more sophistication and ingest multiple years of process history and apply machine learning algorithms. This process history data usually includes vibrational sensors, upstream and downstream flows, pressures, temperatures along with data stored in the manually collected operator log systems.

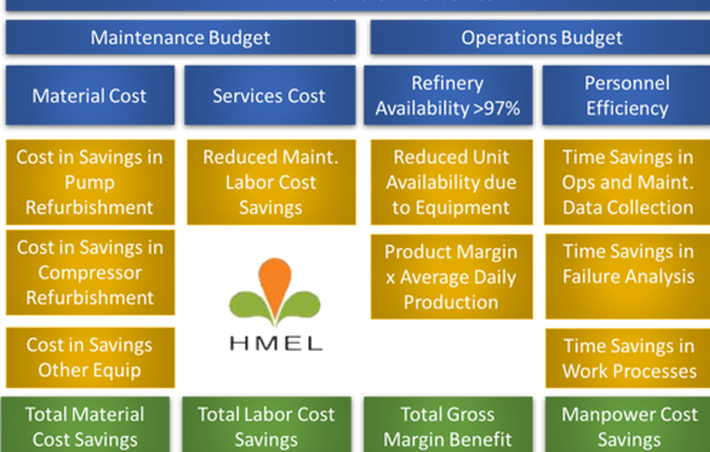

HMEL has established performance indicators for the future (KPI’s) and identified significant savings for the company in material cost, services cost, refinery availability and personnel efficiency. These savings will not come from performing maintenance the old “reactive way”. This will come from becoming smarter about using the data already collected and a few machine learning algorithms bundled in an Analytics solution.

This article was originally posted on ARC Advisory Group.