- Analytics & Modeling - Predictive Analytics

- Application Infrastructure & Middleware - Data Visualization

- Functional Applications - Remote Monitoring & Control Systems

- Infrastructure as a Service (IaaS)

- Platform as a Service (PaaS) - Edge Computing Platforms

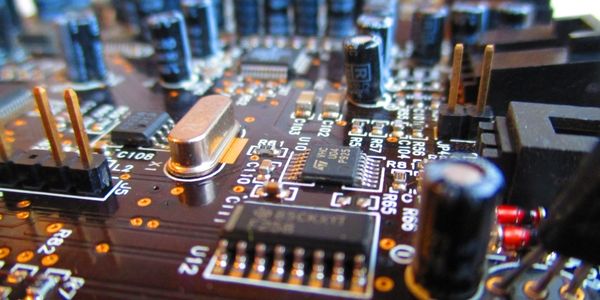

- Electronics

- Maintenance

- Predictive Maintenance

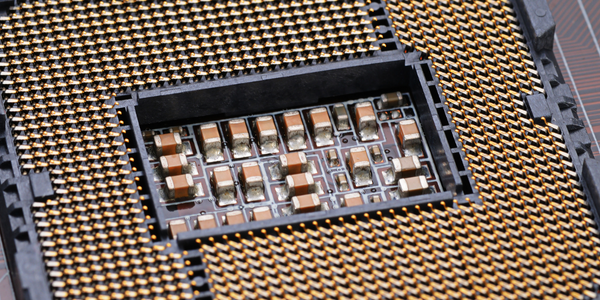

In order to scale up operations, loT Systems’ client needed a system to monitor vacuum pumps and provide managers with actionable data at near real-time speeds from anywhere, at any time, and on any device. The vacuum pumps are part of vertical furnaces that prepare semiconductor wafers at precise temperatures and pressures according to their clients’ exact specifications. If a pump was about to fail and a manager did not see the alarm, it could lead to a scrap event, costing the client revenue, delaying production with unplanned downtime, and increasing overall manufacturing costs. Managers could not see alarms in real time unless they physically walked around the floor, making predictive maintenance and preventing scrap events harder as the client scaled upwards.

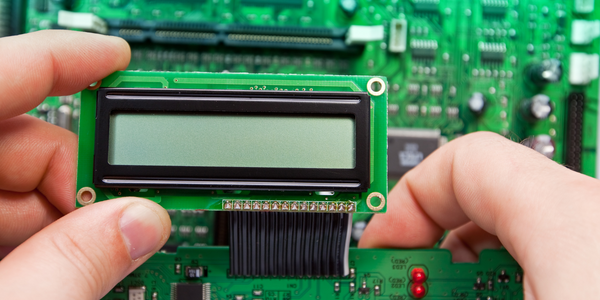

IoT Systems installed the SenseQ edge computing solution. SenseQ monitors the data coming from the sensors on the pump and sends alarms to managers via email or SMS when the data indicates that the pump is about to fail. SenseQ’s dashboard, which works on the equipment owner’s smartphone or tablets, also allows managers to visualize data from multiple pumps over longer periods of time without physical inspections or manual data entries. This makes it possible to set benchmarks and evaluate performance over time to make previously invisible information visible.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.