- Application Infrastructure & Middleware - Data Exchange & Integration

- Application Infrastructure & Middleware - Data Visualization

- Functional Applications - Enterprise Asset Management Systems (EAM)

- Functional Applications - Remote Monitoring & Control Systems

- Platform as a Service (PaaS) - Data Management Platforms

- Sensors - Utility Meters

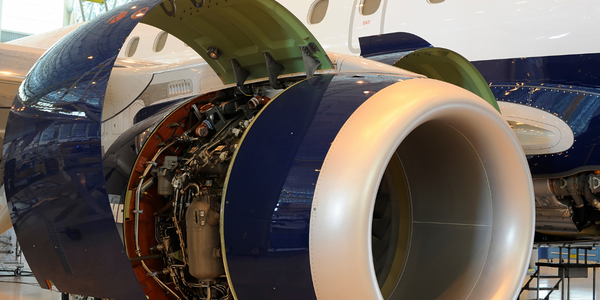

- Discrete Manufacturing

- Factory Operations Visibility & Intelligence

VISIBILITY - Currently unable to see amount of power consumed per machine or plant; need to account for energy used per batch. WASTE - 10% of product fails quality standards, unable to identify point of failure (initial spinning, weaving, final processing, etc). INACCURACY - Acquiring OEE measurements and compiling them is a manual process, which lacks visibility into all parts of the production process and is error-prone. LACK OF INTEROPERABILITY - Outdated machinery still has long, effective lifespans but needs to connect to newer, digital assets

Information transparency is key to get to the root cause of profit losses in manufacturing. The Industrial IoT unleashes the data silos in productions lines, and turns data into real insights. relayr’s Smart Manufacturing Solution allows you to collect, manage, and analyze data straight from production line machines, regardless of the level of automation. With relayr Smart Manufacturing you can easily change your current IT production line environment into a predictive model.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.