- Networks & Connectivity - Gateways

- Sensors - Optical Sensors

- Retail

- Process Manufacturing

- Process Control & Optimization

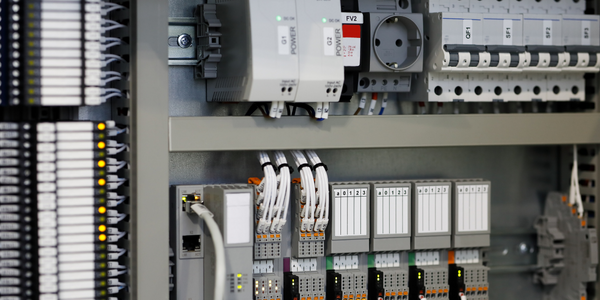

Moxa was asked to provide a connectivity solution for one of the world's leading cosmetics companies. This multinational corporation, with retail presence in 130 countries, 23 global braches, and over 66,000 employees, sought to improve the efficiency of their production process by migrating from manual monitoring to an automatic productivity monitoring system. The production line was being monitored by ABB Real-TPI, a factory information system that offers data collection and analysis to improve plant efficiency. Due to software limitations, the customer needed an OPC server and a corresponding I/O solution to collect data from additional sensor devices for the Real-TPI system. The goal is to enable the factory information system to more thoroughly collect data from every corner of the production line. This will improve its ability to measure Overall Equipment Effectiveness (OEE) and translate into increased production efficiencies. System Requirements • Instant status updates while still consuming minimal bandwidth to relieve strain on limited factory networks • Interoperable with ABB Real-TPI • Small form factor appropriate for deployment where space is scarce • Remote software management and configuration to simplify operations

Moxa's ioLogik E2212 with included Active OPC Server software perfectly met the customer’s requirements. Part of Moxa's Ethernet Micro RTU Controller family, the ioLogik E2122 continues of Moxa's tradition of offering intelligent I/O solutions with active communications architecture. With active "push" architecture, the ioLogik will proactively communicate with the central Real-TPI system instead of waiting for slower and bandwidth-consuming poll-and-response messaging. Moxa's support for active "push" communications helps the customer conserve the limited available bandwidth in factory networks and maintain a constant up-to-date stream of data from connected devices. The other unique component of Moxa's solution is Active OPC Server, which is included with Moxa's I/O products. Moxa's Active OPC Server supports push architecture and allows seamless connections with most SCADA software, including ABB Real-TPI. Compared to third-party OPC servers, the Active OPC Server is a convenient solution designed to work with Moxa's I/O devices that can be freely downloaded from the Moxa website. After evaluating these features, the customer installed ioLogik E2212 units on their production line to interface with optical sensors that maintain a count of how many units are produced. The ioLogik is configured to proactively transmit the counter value to the Active OPC Server every time the value hits a certain threshold, which ensures that an up-to-date count is available to the ABB Real-TPI system. Product Solutions: 1. Active OPC Server Seamlessly connect ioLogik/ioPAC to your SCADA system 2. ioLogik E2212 Smart Ethernet Remote I/O with 8 DIs, 8 DOs, 4 DIOs

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.