ABB Increases Productivity and Reduces Operational Costs

- Platform as a Service (PaaS) - Data Management Platforms

- Platform as a Service (PaaS) - Device Management Platforms

- Equipment & Machinery

- Field Services

- Machine Condition Monitoring

- Predictive Maintenance

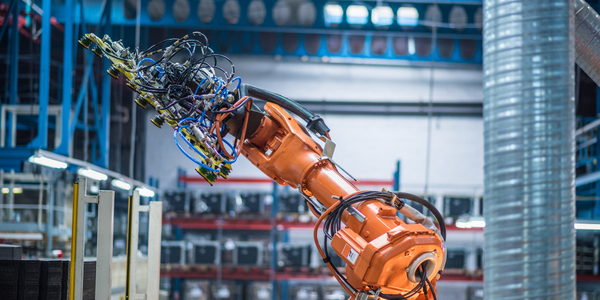

ABB relies on Control Center to monitor connections to its customers' industrial robots for potential problems. As soon as conditions change, ABB engineers want to know about it so that they can act on it. Engineers wanted a solution so that they can anticipate problems by constantly analyzing the information that they receive from the devices. They have developed a set of predictive KPIs, which they share with their customers to help them decide if their equipment requires maintenance.

The greatest benefit of the Jasper platform for ABB is the ability to manage and automate its connected devices on a global scale while maintaining the company's high service reliability and increasing demand for services. Before Jasper, ABB was reacting when customers would call them, and it was difficult to get information to understand precisely what was happening at the device level. With Jasper automation, ABB has real-time monitoring data across their remote devices and can automate responses before incidents occur. Software Components - Jasper Platform - Control Center

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.