- Analytics & Modeling - Big Data Analytics

- Processors & Edge Intelligence - Embedded & Edge Computers

- Electronics

- Facility Management

- Process Control & Optimization

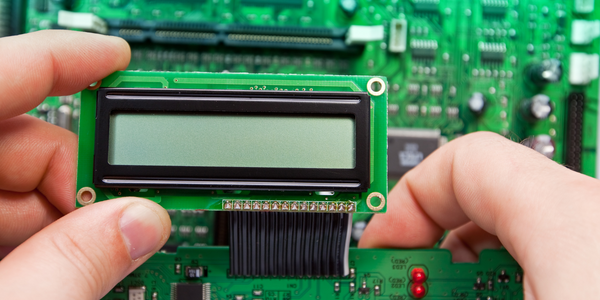

A leading global Chinese LCD panel manufacturer needed to ramp up cost competitiveness and carbon footprint. It needed to cut down on the 47 GWh of annual electrical energy used for compressed air production at the manufacturing site.

Essentially with the data gained by three ionSign's Gluon GMU191 units, Enersize planned and employed optimisation measures, passing on significant savings to the Chinese LCD panel manufacturer. Within 5 months of kick-off, Enersize had delivered energy savings of 15%. Further optimisation measures have been planned already to drive energy savings to 29% over the next 12 months.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.