Technology Category

- Functional Applications - Inventory Management Systems

- Functional Applications - Warehouse Management Systems (WMS)

Applicable Industries

- Education

- Life Sciences

Applicable Functions

- Procurement

- Warehouse & Inventory Management

Use Cases

- Inventory Management

- Picking, Sorting & Positioning

Services

- System Integration

- Training

The Customer

North Texas Pressure Vessels, Inc.

About The Customer

North Texas Pressure Vessels, Inc. is a Texas-based manufacturer. The company was facing significant challenges with their inventory management, with no system in place and inaccurate values and quantities of inventory. This led to difficulties in pricing jobs accurately and high costs of processing Purchase Orders. The company's existing system, Sage 50, did not have the necessary functionality to address these issues. The team at NTPV had considerable experience working with other MRP systems such as Symix and Oracle.

The Challenge

North Texas Pressure Vessels, Inc. (NTPV) was facing a significant challenge with their inventory management. The company had no inventory management system in place, leading to inaccurate values and quantities of inventory. There were no item numbers, and purchasing relied on multiple spreadsheets to determine if there was enough inventory on hand for the production schedule. Inventory costs were not accurate and not up to date, which led to difficulties in pricing jobs accurately due to the lack of true costing of the inventory. The company's existing system, Sage 50, did not have the necessary functionality. Furthermore, the cost of processing Purchase Orders was extremely high, indicating inefficiencies in the purchasing activities.

The Solution

NTPV decided to implement the MISys Manufacturing Software to address their inventory management issues. The team at NTPV, who had considerable experience working with other MRP systems such as Symix and Oracle, found that MISys had the functionality they needed. They worked with a SureStart coach to set up MISys properly and train their personnel. The coach provided excel templates that made it easy to organize the data for uploading into MISys. They loaded 19,000 inventory items into the system. The implementation process involved getting all the players involved and conducting system training before going live. They also had to get some customer reports written for them and spend some money on it. The implementation was successful and they went live on January 1st to start a new year with the new system.

Operational Impact

Quantitative Benefit

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.

Case Study

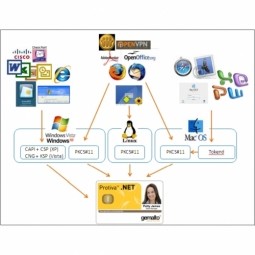

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

IoT platform Enables Safety Solutions for U.S. School Districts

Designed to alert drivers when schoolchildren are present, especially in low-visibility conditions, school-zone flasher signals are typically updated manually at each school. The switching is based on the school calendar and manually changed when an unexpected early dismissal occurs, as in the case of a weather-event altering the normal schedule. The process to reprogram the flashers requires a significant effort by school district personnel to implement due to the large number of warning flashers installed across an entire school district.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

Case Study

Revolutionizing Medical Training in India: GSL Smart Lab and the LAP Mentor

The GSL SMART Lab, a collective effort of the GSL College of Medicine and the GSL College of Nursing and Health Science, was facing a challenge in providing superior training to healthcare professionals. As clinical medicine was becoming more focused on patient safety and quality of care, the need for medical simulation to bridge the educational gap between the classroom and the clinical environment was becoming increasingly apparent. Dr. Sandeep Ganni, the director of the GSL SMART Lab, envisioned a world-class surgical and medical training center where physicians and healthcare professionals could learn skills through simulation training. He was looking for different simulators for different specialties to provide both basic and advanced simulation training. For laparoscopic surgery, he was interested in a high fidelity simulator that could provide basic surgical and suturing skills training for international accreditation as well as specific hands-on training in complex laparoscopic procedures for practicing physicians in India.

Case Study

Implementing Robotic Surgery Training Simulator for Enhanced Surgical Proficiency

Fundacio Puigvert, a leading European medical center specializing in Urology, Nephrology, and Andrology, faced a significant challenge in training its surgical residents. The institution recognized the need for a more standardized and comprehensive training curriculum, particularly in the area of robotic surgery. The challenge was underscored by two independent studies showing that less than 5% of residents in Italian and German residency programs could perform major or complex procedures by the end of their residency. The institution sought to establish a virtual reality simulation lab that would include endourological, laparoscopic, and robotic platforms. However, they needed a simulator that could replicate both the hardware and software of the robotic Da Vinci console used in the operating room, without being connected to the actual physical console. They also required a system that could provide both basic and advanced simulation training, and a metrics system to assess the proficiency of the trainees before they performed surgical procedures in the operating theater.

Case Study

Edinburgh Napier University streamlines long-distance learning with Cisco WebEX

• Geographically dispersed campus made in-person meetings costly and inconvenient.• Distance-learning programs in Malaysia, India, and China required dependable, user-friendly online tools to maximize interaction in collaborative workspaces.• Virtual learning environment required a separate sign-in process, resulting in a significant administrative burden for IT staff and limited adoption of collaboration technology.